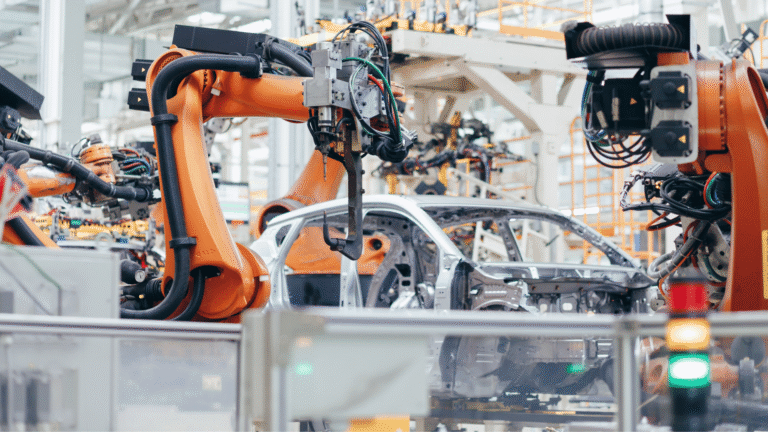

A global automotive components manufacturer partnered with Eternal Robotics to modernize Quarter Panel Inspection for the YHB Quarter Panel RH. The goal: to implement real-time defect detection for spot welds, holes, and nuts using advanced computer vision technology, all integrated seamlessly into a PLC-based production line.

The result? A compact, AI-powered computer vision system that delivers foolproof quality checks, reduces manual errors, and boosts traceability across the production floor.

Unlock Key Outcomes

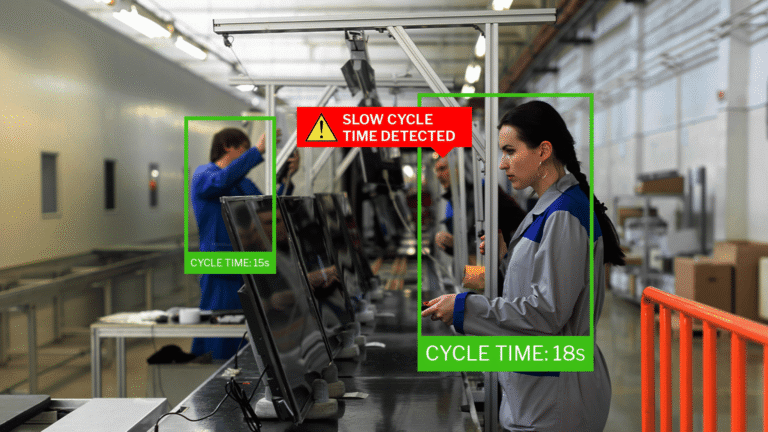

- Quarter Panel Inspection using high-precision computer vision

- Real-time detection of welds, holes, and nuts

- Seamless integration with existing PLC systems and safety infrastructure

- Dashboards for live defect tracking and performance analytics

- Manpower optimization and predictive maintenance with AI insights

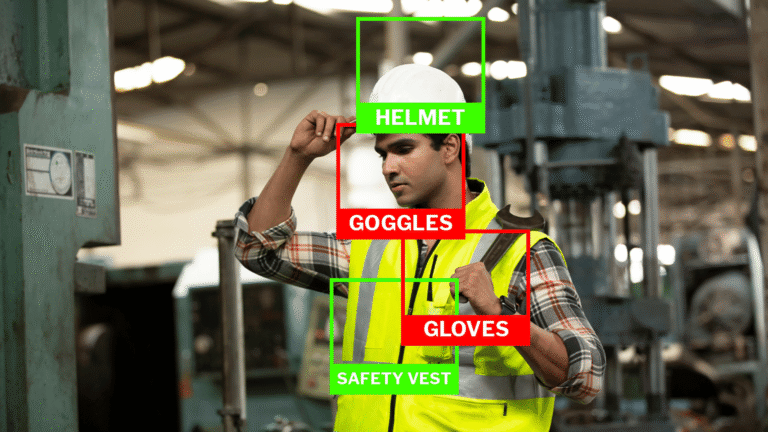

Ready to See the Impact of Intelligent Automation?

Download the full case study now to discover how Eternal Robotics enabled high-speed, high-accuracy Quarter Panel Inspection using computer vision—empowering smarter manufacturing for a global automotive leader.

Modernize Quality Control. Eliminate Defects. Drive AI-Powered Precision.