A leading radiator manufacturer partnered with Hypervise.AI to transform their radiator core inspection process using cutting-edge computer vision technology. The objective: to automate defect detection with unmatched speed and accuracy while seamlessly integrating into the existing production workflow.

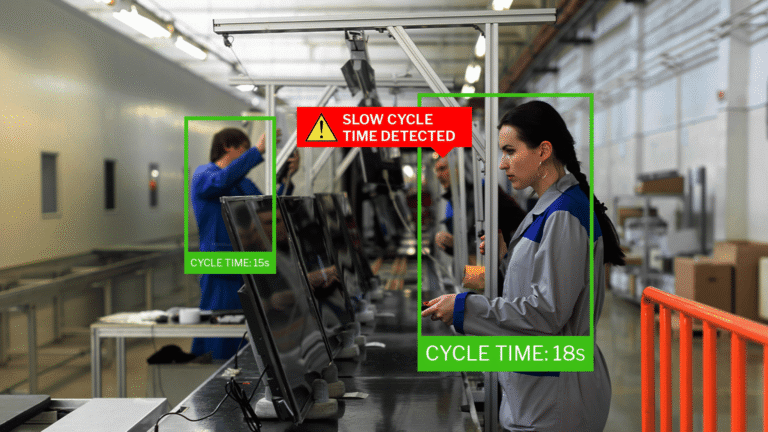

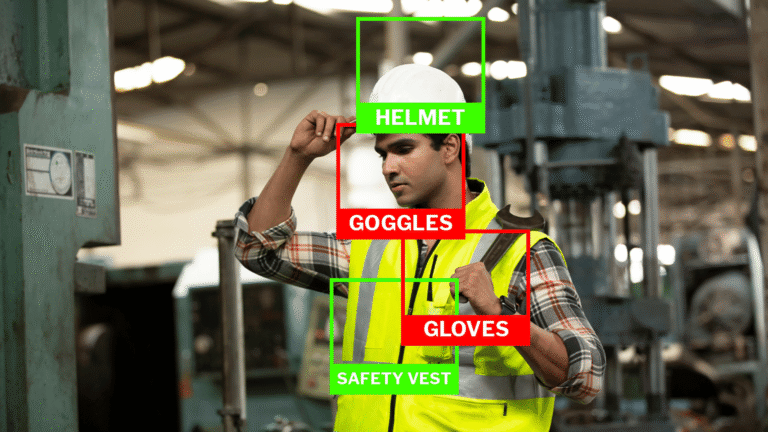

By leveraging AI and computer vision, Hypervise.AI deployed a robust inspection system capable of identifying minute defects—such as core misalignments, bent fins, weld inconsistencies, and surface anomalies—ensuring superior quality and operational efficiency.

Key Outcomes

- Automated radiator core inspection using high-speed computer vision

- Real-time identification of structural and surface defects

- Seamless integration with PLC-based manufacturing systems

- Improved defect traceability and audit-friendly reporting

- Reduced inspection time and manual dependency

Ready to Modernize Your Quality Inspection?

Download the case study to discover how Hypervise.AI is redefining radiator manufacturing through intelligent automation and precision-driven inspection.