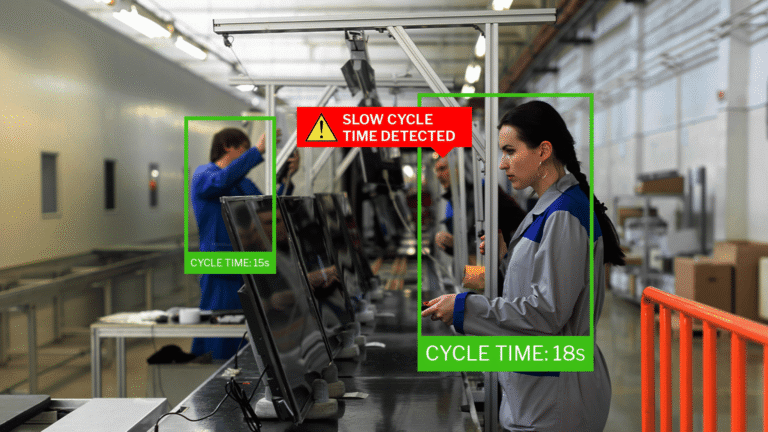

In today’s fast-paced automotive manufacturing environment, achieving consistent and scalable Instrument Cluster Inspection is critical to maintaining quality and customer trust. A leading global automotive manufacturer partnered with Eternal Robotics to overcome persistent challenges—including inconsistent inspection standards, time-consuming manual checks, and the inability to scale efficiently.

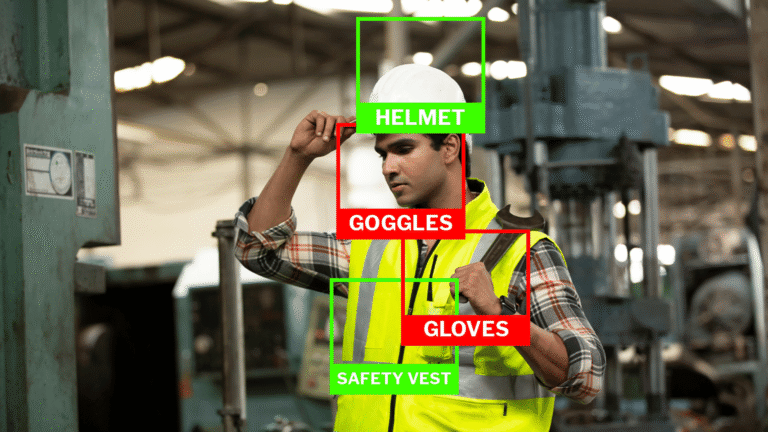

Our cutting-edge computer vision-based IP Cluster Inspection System was deployed across production lines to automate quality control. The result? Near-perfect defect detection accuracy, elimination of human error, and real-time visibility that streamlines throughput while ensuring compliance with rigorous OEM standards.

Key Outcomes of Vision-Enabled Instrument Cluster Inspection:

- Automated IP Cluster Inspection using AI and computer vision

- Real-time detection of defects such as scratches, misalignments, or incomplete assemblies

- Seamless integration with existing PLC-based production systems

- Scalable architecture for multi-line and multi-model production

- Intuitive dashboards for defect analytics, traceability, and performance optimization

Discover How to Transform Inspection with AI

Download the full case study now to see how Eternal Robotics is redefining IP Cluster Inspection and Instrument Cluster Inspection with advanced computer vision systems that deliver reliability, speed, and precision at scale.