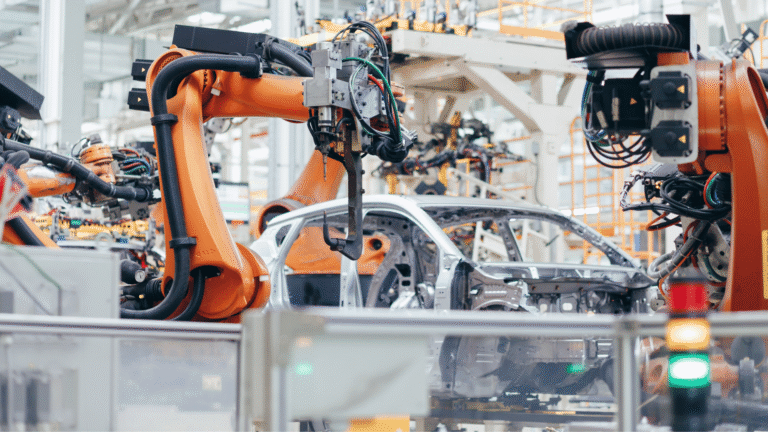

A top Indian automotive manufacturer collaborated with Eternal Robotics to automate the underbody component inspection process using AI-powered machine vision. The challenge: reduce manual errors, boost inspection accuracy, and align with high-speed production. Eternal Robotics deployed a computer vision-based system that detects and classifies components like brake pipes, fuel lines, and suspension bolts in real time—eliminating inefficiencies in traditional inspection methods.

The result? A high-throughput, AI-driven inspection solution that ensures consistent quality, minimizes rework, and scales effortlessly across production lines—without disrupting factory operations.

Unlock Key Outcomes in Component Inspection

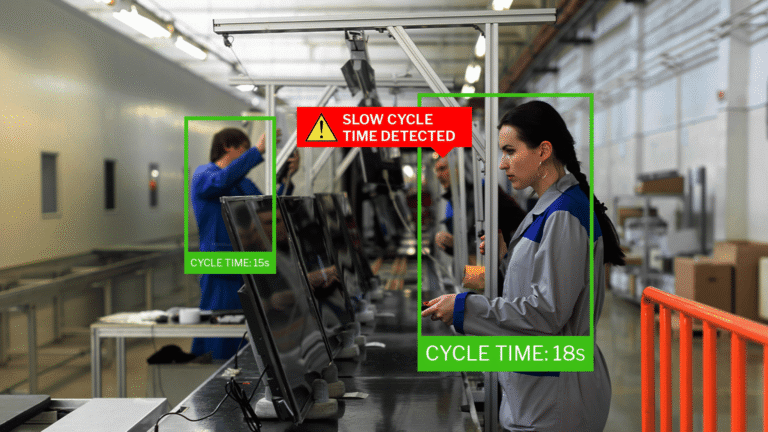

- Real-time detection of brake pipes, fuel pipes, suspension bolts, and more

- 95%+ classification accuracy across 1,000+ vehicles daily

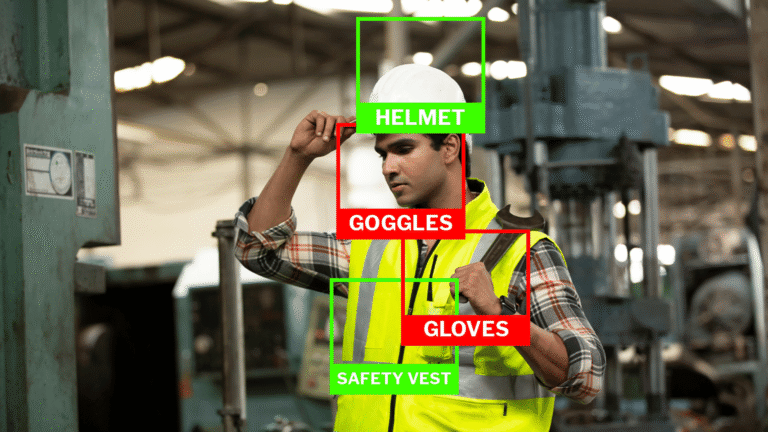

- Error detection, presence checks, and fitment verification in real time

- Seamless integration with existing conveyor systems and PLC infrastructure

- Live quality analytics dashboard for actionable insights

- Scalable for multi-line deployment across high-volume plants

Ready to revolutionize underbody inspections with AI?

Download the full case study to discover how Eternal Robotics enhanced quality control and production efficiency with computer vision in automotive manufacturing.