A leading battery manufacturer partnered with Hypervise.AI to overcome inefficiencies in manual battery inspection and ensure defect-free production. Our computer vision-powered inspection system significantly enhanced OCR accuracy, defect detection, and barcode/QR code verification, optimizing battery quality control and reducing production errors.

See the Impact of AI-Powered Battery Inspection

Discover how Hypervise.AI helped achieve:

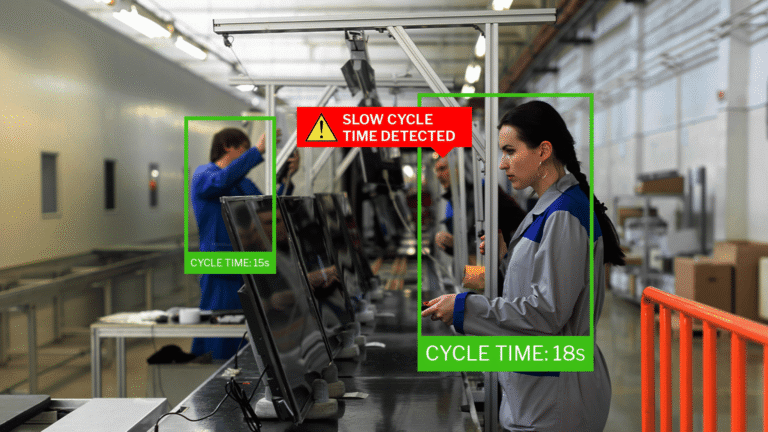

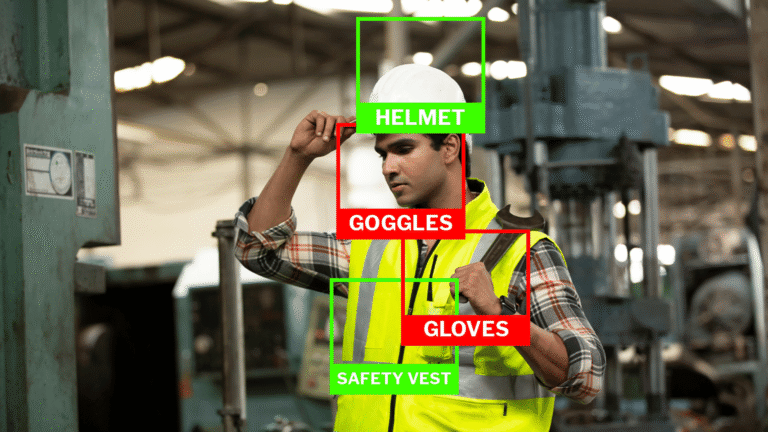

- High-accuracy battery defect detection with computer vision

- Reliable barcode & OCR verification for precision tracking

- Real-time monitoring & analytics for production insights

- Seamless scalability across multiple battery production lines

Ready to Elevate Your Battery Manufacturing Process?

Download the full case study now and explore how AI-driven computer vision is transforming battery inspection and quality control across the industry.

Enhance accuracy. Minimize defects. Scale with confidence.