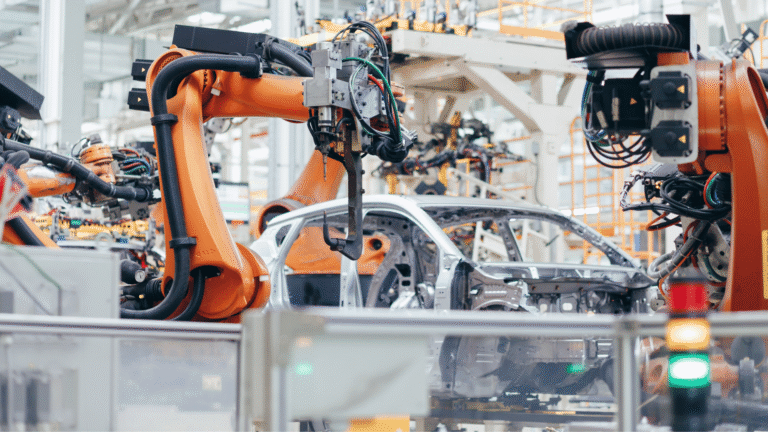

Many factory owners in India are familiar with Industry 4.0. It brought us smart factories, with machines connected to the internet, gathering data and automating tasks. The goal was efficiency, often by removing the human element to reduce errors. Think of it as the rise of the automated factory. But now, a new chapter is beginning, and it’s important to understand the shift from Industry 4.0 to Industry 5.0 in India.

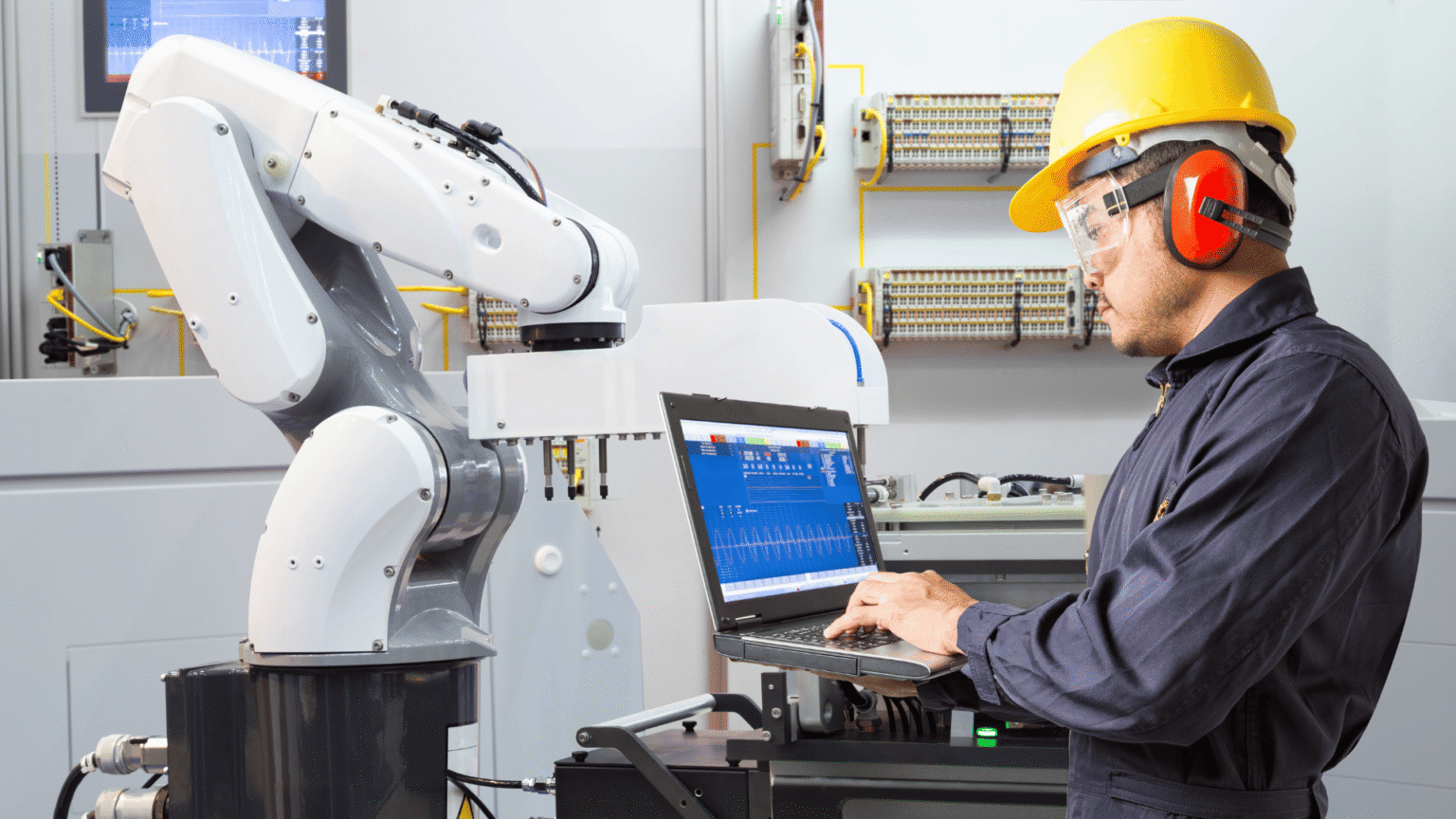

Industry 5.0 doesn’t replace the fourth revolution; it refines it. It puts people back at the center of the factory. The core idea is simple: AI should help people, not replace them. While Industry 4.0 focused on machine-to-machine communication, Industry 5.0 is about creating seamless collaboration between humans and smart systems. It combines the speed and precision of machines with the creativity, critical thinking, and expertise of the Indian worker.

Three Pillars of Industry 5.0 (Human-Centric, Sustainable, Resilient)

Understanding what Industry 5.0 means for manufacturing in India becomes clearer when you look at its three core principles. These pillars guide how technology should be implemented on the factory floor for long-term success, especially in a dynamic market like India.

Human-Centric Approach

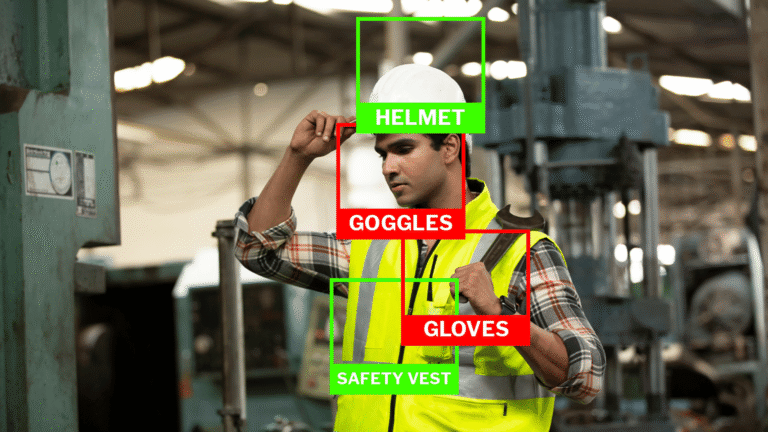

This is the most significant shift. Instead of designing processes to eliminate people, technology is designed to empower them. It acts as a co-worker, taking on repetitive or strenuous tasks so skilled operators can focus on quality, problem-solving, and innovation. This respects the deep knowledge of experienced workers—an invaluable asset in India’s diverse manufacturing landscape.

Sustainability

Industry 5.0 pushes factories to use technology for more than just profit. It’s about building processes that are environmentally responsible. This means using AI to optimize energy consumption, reduce material waste, and support circular economies. For Indian exporters, meeting global sustainability standards is no longer optional—and this approach provides a clear path forward.

Resilience

Recent global events have shown how fragile supply chains can be. A resilient factory is one that can adapt to sudden changes and disruptions. Industry 5.0 strengthens resilience by creating flexible production systems where humans and AI can quickly reconfigure processes to handle new products or unexpected challenges—a crucial advantage for businesses dealing with varied product lines and fluctuating demand.

How Indian SMEs Can Join Industry 5.0 Without Huge Investment

The term industrial revolution might sound expensive, but embracing Industry 5.0 doesn’t require a complete factory overhaul. For Small and Medium Enterprises (SMEs) in India, the path is through smart, incremental steps. You don’t need to buy all-new machinery—the focus is on upgrading what you already have.

It starts with identifying specific challenges—like quality control issues or production bottlenecks—and applying targeted AI solutions that integrate with your existing equipment and workforce. Modern platforms are user-friendly, enabling your team to operate them without needing a data science background. This makes the transition affordable and ensures the technology is tailored to your needs.

Hypervise.ai: A Real Example of Human-First AI

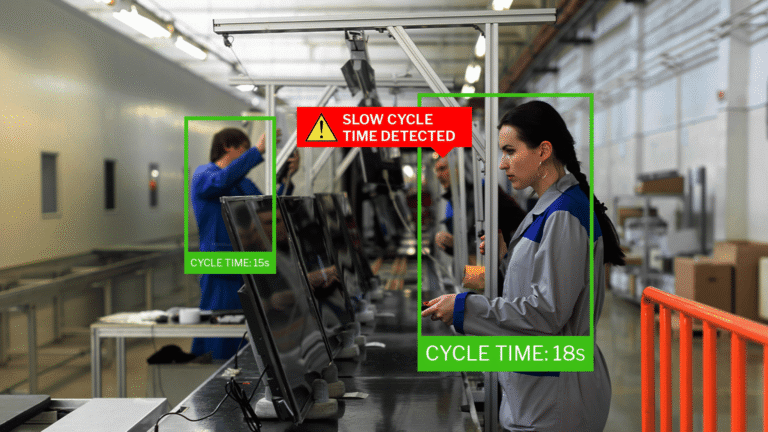

To see Industry 5.0 in action, look no further than Hypervise.ai—a perfect example of a human-centric AI system built for factory floors. Instead of replacing quality inspectors, it strengthens their decision-making. The system uses cameras and AI to detect potential defects, but the human operator still makes the final judgment.

This technology learns from your best workers, captures their expertise, and distributes that knowledge across all shifts. It empowers every operator to perform at the level of your most experienced employee. This is the essence of Industry 5.0: technology that enhances human skill, leading to better quality and less waste—without sidelining the workforce.

Eternal Robotics’ Role in Bringing Industry 5.0 to India

The development of platforms like Hypervise.ai is part of a larger vision. Eternal Robotics is focused on creating solutions that are not only technologically advanced but also practical and relevant for the Indian manufacturing context. The goal is to build tools that understand the pressures of diverse product ranges, the value of skilled labor, and the demands of a competitive global export market.

By championing this human-first approach, Eternal Robotics is helping shape what Industry 5.0 looks like in India—a collaborative model where technology serves people, driving growth and innovation from the ground up.

Your First Question Before Starting

Beginning the journey into Industry 5.0 can feel overwhelming. Instead of asking about complex technologies, start with a simple, human-focused question:

“Which process in my factory could be significantly amplified by capturing and augmenting my best worker’s skill?”

This question shifts your focus to your greatest asset: your people. It encourages collaboration, not replacement. Whether it’s in visual inspection, machine setup, or final assembly, identifying that key area of human expertise is the first and most important step. It ensures your initial investment in Industry 5.0 delivers real, measurable value.

Industry 5.0 is not a distant concept; it’s a practical strategy available today. For Indian factories, it offers a path to becoming more competitive, sustainable, and resilient by combining human ingenuity with intelligent technology. It’s about empowering your workforce to build the future.