Manufacturing companies are burning millions on AI projects that never deliver. Despite the hype around smart factories and Industry 4.0, the challenges of AI adoption in manufacturing are causing 85% of initiatives to stall or fail completely.

Why? Because implementing AI in a factory isn’t like installing software on your laptop. It’s messy, complicated, and full of surprises that can derail even the best-planned projects.

If you’re considering AI for your manufacturing operations, here are the five biggest obstacles you’ll face—and practical steps to overcome them.

1. Your Data is a Hot Mess (And That’s Problem #1)

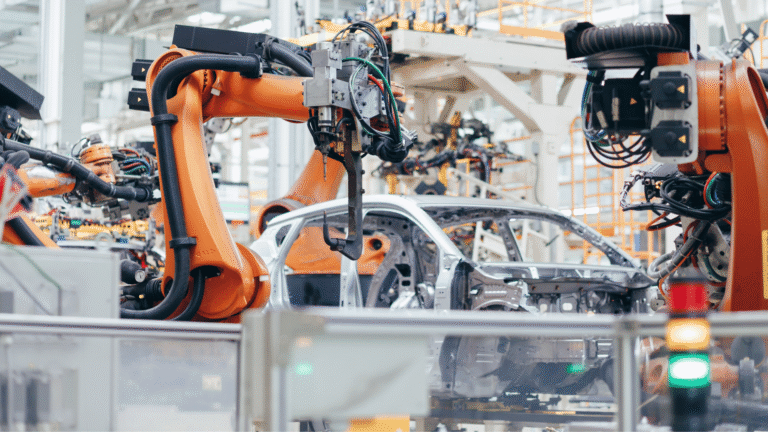

Walk through any manufacturing facility and you’ll see the problem immediately. A 1990s PLC controls your main production line. Your quality sensors dump data into Excel sheets. Your ERP system lives in its own world, completely disconnected from your maintenance software.

This fragmented data landscape creates massive challenges for industrial AI. Machine learning algorithms need clean, consistent data to function properly. When your information comes from dozens of different systems in various formats, AI models produce garbage results.

Here’s what makes this worse: Gartner research shows that manufacturers spend 70% of their AI project budgets just getting data ready for analysis. Most executives never budget for this reality.

The solution: Start with data governance. Before you even think about AI algorithms, standardize how your systems collect and store information. Create integration platforms that connect your equipment. Establish data quality standards that everyone follows.

2. Nobody Knows How to Use It

You found a brilliant data scientist with a PhD in machine learning. Great start. Now ask them to troubleshoot a conveyor belt malfunction or explain why your injection molding temperature varies by 3 degrees.

…Crickets…

This skills gap represents one of the biggest barriers to manufacturing AI. Successful implementation requires people who understand both advanced algorithms and manufacturing processes. These professionals are rare and expensive.

Most companies try hiring consultants to bridge this gap. While consultants can kickstart projects, they create long-term dependency problems. When they leave, so does the knowledge.

The smart approach: Train existing engineers in basic AI concepts while teaching data scientists about manufacturing operations. Cross-functional teams with shared knowledge deliver better results than star individuals working in isolation.

3. The Money Doesn’t Add Up (At Least Not Quickly)

Traditional manufacturing investments follow predictable patterns. Buy a CNC machine for $200,000, calculate labor savings, determine payback period. Simple math.

AI breaks this model completely.

You’ll spend heavily upfront on cloud infrastructure, edge computing hardware, specialized software licenses, and new personnel. Meanwhile, AI systems need 18–24 months to mature and demonstrate measurable value. According to Boston Consulting Group, only 30% of manufacturers see positive ROI from AI within the first two years.

This timing mismatch kills projects. Executives expect quarterly returns while AI delivers long-term transformation. Companies abandon promising initiatives just before they would have paid off.

The risk isn’t technical—it’s financial impatience. Set realistic expectations from day one. Identify use cases with clear, measurable outcomes. Start with smaller projects that can demonstrate value while larger initiatives develop.

4. Your Workers Think It’s the Enemy

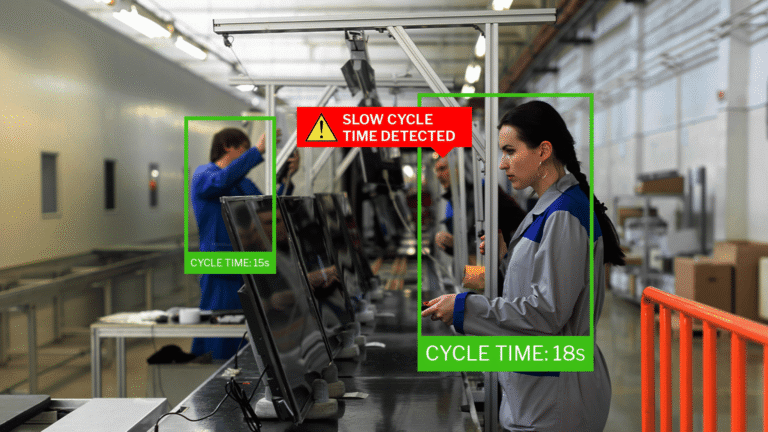

Meet Sarah, your best machine operator. She’s run the same production line for 15 years. She knows exactly how the equipment sounds when it’s running properly. She can predict problems days before they happen.

Now you want her to follow recommendations from an algorithm she doesn’t understand.

Sarah’s resistance isn’t stubbornness—it’s experience. She’s seen plenty of technology promises fail. She worries about job security. She doesn’t trust systems that can’t explain their reasoning.

This human element causes more project failures than any technical issue. Common pitfalls of AI deployment in manufacturing center around change management, not algorithms.

The solution: Involve workers from the beginning. Explain how AI enhances their expertise rather than replacing it. Provide transparency into decision-making processes. When Sarah understands that AI validates her instincts and catches things she might miss, resistance transforms into advocacy.

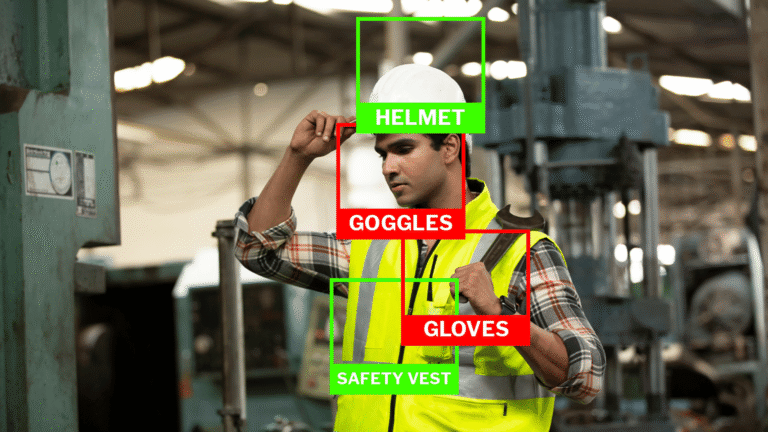

5. Cybersecurity Nightmares Keep Everyone Awake

Every AI system you connect creates another potential entry point for attackers. Legacy equipment designed for isolated operation suddenly needs internet connectivity. Your factory becomes vulnerable to the same threats that hit banks and hospitals.

The stakes are enormous. A cyberattack can shut down production lines, damage expensive equipment, or steal valuable intellectual property. Colonial Pipeline’s 2021 shutdown demonstrated how quickly operational technology attacks can cascade.

Manufacturing cybersecurity requirements vary globally. European GDPR rules differ from American standards. Asian markets have their own compliance frameworks. As AI systems become more sophisticated, regulators demand greater explainability and audit trails.

The solution: Design cybersecurity into your AI architecture from the beginning. Segment networks to limit breach impact. Implement zero-trust principles for all connected systems. Regular security audits become essential maintenance, not optional activities.

The Major Concern in Enterprise AI Adoption

The biggest concern isn’t technical—it’s strategic misalignment.

Most manufacturers treat AI like any other technology purchase. They focus on features and capabilities while ignoring organizational readiness. They expect plug-and-play solutions in environments that require comprehensive transformation.

Overcoming AI implementation issues starts with honest assessment:

- Do you have the data infrastructure?

- The right skills?

- The organizational culture?

- Financial patience?

- Most importantly, clear business objectives that AI can address?

Your Path Forward: Making AI Work in Manufacturing

Success requires systematic execution across five areas:

- Start with Strategy: Identify specific business problems AI can solve. Focus on use cases with measurable outcomes like reducing downtime or improving quality metrics.

- Fix Data First: Invest in integration platforms and data governance before building AI models. Clean data delivers better results than sophisticated algorithms working with garbage inputs.

- Build Internal Capabilities: Train existing employees rather than depending entirely on outside consultants. Your team understands your processes better than any external expert.

- Design for Security: Treat cybersecurity as a core requirement, not an add-on feature. Implement security measures during design, not after deployment.

- Manage Change Actively: Involve stakeholders throughout your organization. Address concerns directly. Demonstrate how AI supports rather than threatens existing expertise.

The industrial AI adoption barriers and solutions outlined here require commitment and patience. However, manufacturers who address these challenges systematically are achieving remarkable results. They’re reducing maintenance costs by 25%, improving quality metrics by 30%, and building competitive advantages that compound over time.

Ready to transform these challenges into competitive advantages? Discover how our manufacturing AI solutions help companies like yours implement successful AI strategies that deliver real results.