Key Takeaways

- Beyond the Basics: Standard AI struggles with real-world variables such as dirt, occlusion, and poor lighting.

- Edge Case Mastery: Superior PPE detection software uses complex datasets to distinguish between holding a helmet and wearing one.

- Compliance Automation: Automated monitoring ensures consistent industrial safety compliance without constant human supervision.

- Real-Time Alerts: Immediate notifications of safety breaches help prevent accidents before they occur.

What Is PPE Detection Software?

PPE detection software is a specialized application of computer vision technology designed to automatically monitor industrial environments for Personal Protective Equipment compliance. By analyzing live video feeds from workplace cameras, these systems identify whether workers are correctly wearing safety gear—such as hard hats, high-visibility vests, and safety goggles—and instantly alert safety managers to violations. This automation streamlines risk management and enhances overall site safety.

The Status Quo: Why Basic AI Fails in the Real World

In the rapidly growing field of workplace safety AI, the market is saturated with basic computer vision models that perform well in controlled demonstrations but falter in the chaotic reality of construction sites and factory floors.

The current status quo is relatively simple: basic AI can easily detect a pristine, bright yellow helmet against a contrasting background. These generic models are typically trained on stock photography or idealized datasets where safety gear is clean, lighting is perfect, and subjects face the camera directly.

However, relying on such rudimentary systems creates a false sense of security for safety managers who believe their sites are fully monitored. When conditions shift from sterile testing environments to dusty, dynamic worksites, the limitations of standard detection algorithms become immediately—and dangerously—apparent.

The Challenge: Edge Case Detection in Industrial Environments

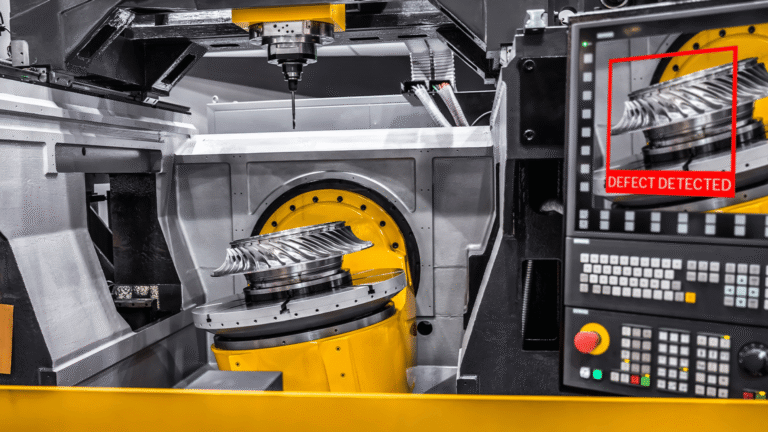

Real-world industrial environments are rarely ideal, and the true test of PPE detection software lies in its ability to handle edge cases—scenarios that deviate from standard training data.

Consider these variables:

- A hard hat covered in months of concrete dust and grime

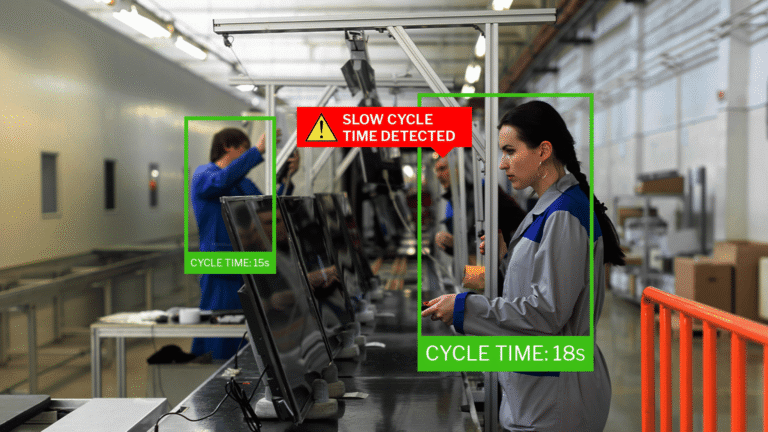

- A worker holding a helmet instead of wearing it

- Poor lighting during night shifts or in shadowed warehouse zones

In such cases, basic models frequently fail—either missing violations entirely or generating excessive false positives that fatigue safety teams. Effective detection requires contextual understanding: distinguishing between PPE merely present in a frame and PPE that is actively protecting a worker.

The Hypervise Difference: Solving Complex Safety Scenarios

This is where the Hypervise difference becomes critical to operational success. Our models are not trained on generic safety images alone but on complex, proprietary datasets specifically designed to handle difficult edge cases.

By exposing the AI to thousands of images featuring dirty, scratched, and partially occluded PPE—across varying lighting conditions and camera angles—the system learns to recognize safety gear in its real working state.

More importantly, advanced contextual algorithms accurately differentiate between a worker holding a hard hat and one wearing it. This level of precision is a strong indicator of industry experience, proving the solution is not vaporware but a robust tool built for real industrial safety challenges. By addressing edge cases effectively, safety protocols remain enforced even under non-ideal conditions.

Comparing Basic Computer Vision vs. Advanced PPE Detection

To understand the value of high-end detection systems, it is helpful to compare their capabilities against standard, off-the-shelf computer vision models.

| Feature | Basic Computer Vision | Advanced Edge Case AI |

| Condition Recognition | Detects only clean, bright, new equipment | Identifies dirty, worn, or painted gear |

| Context Awareness | Flags PPE as compliant if visible anywhere in the frame | Distinguishes between “worn” vs. “carried” PPE |

| Lighting Adaptability | Fails in low-light, backlit, or high-contrast scenes | Optimized for variable industrial lighting |

| False Positive Rate | High (often flags background objects as PPE) | Low (filters out irrelevant objects) |

| Occlusion Handling | Requires full object visibility | Detects PPE even when partially blocked |

Improving Industrial Safety Compliance with Automation

Deploying robust PPE detection software is not just a technological upgrade—it is a strategic move toward comprehensive industrial safety compliance. Automated systems provide 24/7 monitoring capabilities that human oversight cannot match, ensuring safety standards are enforced across every shift.

By leveraging edge case detection, organizations can reduce liability while demonstrating a proactive commitment to worker safety. For teams ready to move beyond basic monitoring and deploy systems that understand the difference between safe behavior and risk, choosing the right technology partner is essential. We invite you to explore our capabilities and schedule a demo to see how the system adapts to your unique environment.

Frequently Asked Questions

Advanced PPE detection software uses high-dynamic-range (HDR) processing and specialized low-light training datasets. This enables accurate identification of safety equipment shapes and contours even in dimly lit areas such as tunnels or night-shift sites.

Yes. Advanced systems leverage pose estimation and contextual analysis to determine PPE placement relative to the worker’s body. A worker carrying a helmet is correctly flagged as non-compliant until it is worn.

High-quality models are trained on real-world datasets containing worn, dirty, and scratched equipment. This ensures PPE is recognized in actual field conditions, not just in pristine scenarios.

Most modern PPE detection solutions are hardware-agnostic and integrate seamlessly with existing IP camera systems, enabling upgrades without costly hardware replacements.