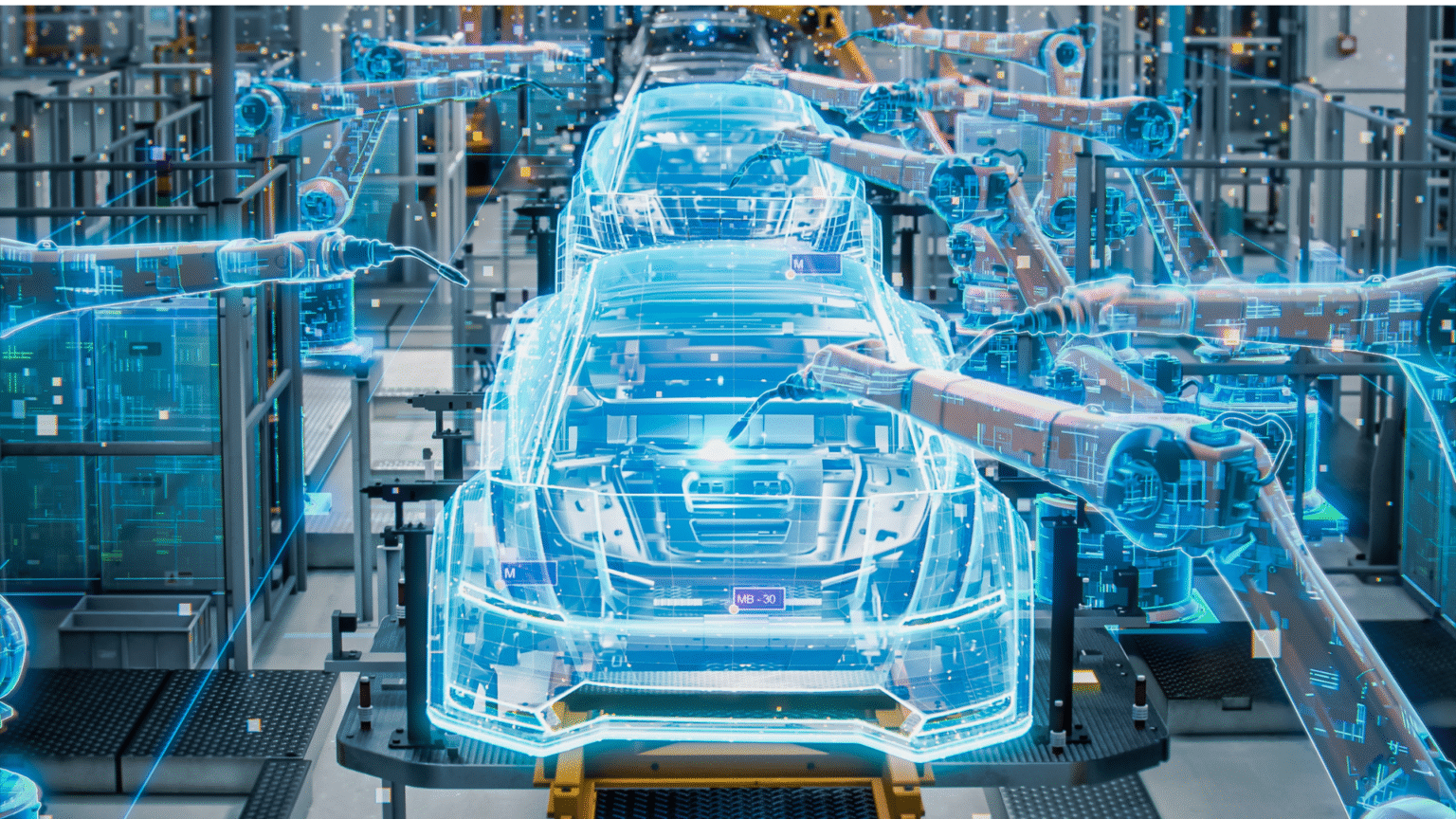

The automotive manufacturing sector is undergoing a pivotal transformation. With increasing demand for high precision, faster throughput, and reduced defects, manufacturers are turning to advanced technologies to modernize operations. At Hypervise, we believe computer vision is at the forefront of this evolution—redefining what’s possible on the factory floor.

Hypervise’s AI-powered computer vision solutions are engineered to tackle some of the most complex and critical challenges faced by automotive manufacturers today. From defect detection to operator assistance, our systems seamlessly integrate into production environments, delivering real-time insights, error-proof processes, and measurable ROI.

Below are four high-impact ways Hypervise Vision AI is accelerating digital transformation in automotive manufacturing.

1. AI-Powered Defect Detection Across Production Lines

Traditional machine vision systems, with rigid rule-based configurations, are often limited in adaptability. Hypervise’s computer vision platform, built with deep learning models, goes beyond static rules by learning from data and adapting to new product variations or changes in workflow.

Whether it’s identifying metal surface defects, glass irregularities, missing components, or faulty wiring, Hypervise enables real-time visual monitoring across critical touchpoints—preventing downstream issues and ensuring a higher first-pass yield. Our models process high-resolution image and video feeds at the edge, flagging anomalies instantly and triggering alerts for rapid intervention.

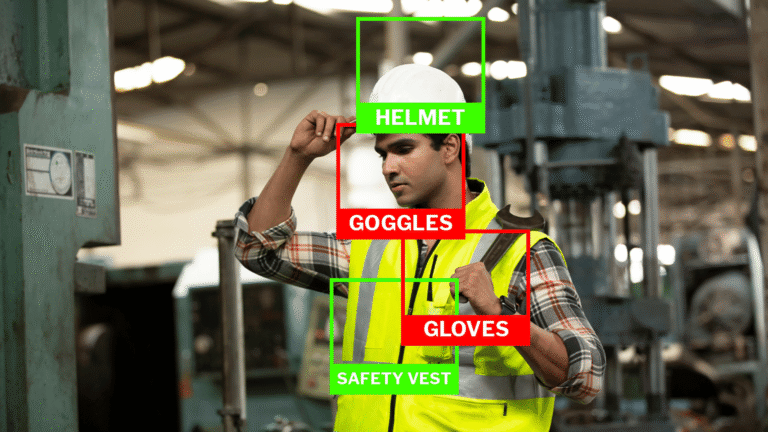

2. Vision AI for Error-Proofing Human Operations

Not every assembly or inspection process can be redesigned to eliminate human error. That’s where Hypervise comes in. Our vision AI modules continuously monitor tasks on the line—detecting out-of-order procedures, verifying correct tool usage, and ensuring proper part placement.

By understanding operator behavior and workflow patterns, Hypervise’s systems not only catch mistakes but also prevent them by guiding workers in real-time. This significantly enhances operational reliability and reduces rework, even in highly manual or semi-automated settings.

3. Advanced OCR/OCV for Traceability and Compliance

With Hypervise’s Optical Character Recognition (OCR) and Optical Character Verification (OCV) capabilities, automotive manufacturers gain full visibility over part identification and traceability.

OCR enables the dynamic reading of serial numbers, batch codes, and component labels, converting unstructured visual data into structured, usable insights for MES and ERP systems. Our OCV modules further enhance accuracy by validating characters against predefined templates—ideal for critical compliance checks in processes with low variation.

These tools ensure every component is correctly tracked, matched, and certified—reducing human error and strengthening chain-of-custody visibility.

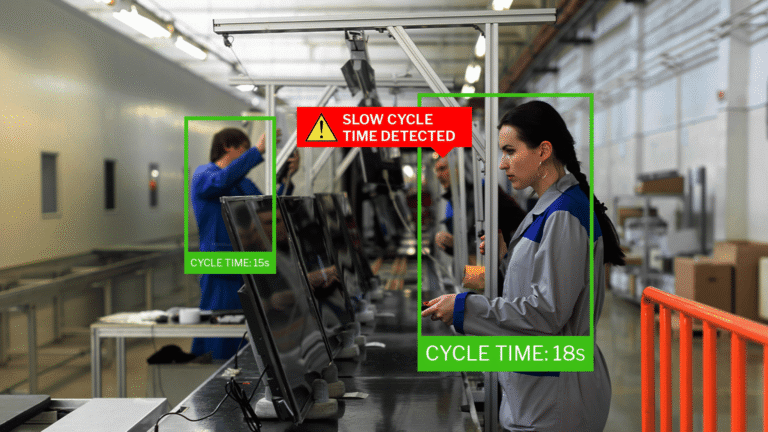

4. Enhancing Operator Efficiency Through Worker Augmentation

Hypervise is not just about automation—it’s about augmentation. By providing visual guidance, quality feedback, and real-time decision support, our platform empowers workers to perform with greater speed and accuracy.

Operators can rely on Hypervise to:

- Confirm visual work instructions are followed.

- Validate part/tool readiness at each step.

- Detect and guide corrections when deviations occur.

The result? Faster onboarding, lower error rates, and reduced mental fatigue. In turn, this promotes safer workplaces, reduces churn, and builds a more capable workforce—ready to adapt to rapidly evolving production demands.

The Road Ahead

Modernizing automotive manufacturing isn’t optional—it’s a competitive necessity. At Hypervise, we’re enabling OEMs and Tier-1 suppliers to adopt next-generation computer vision systems that scale, adapt, and deliver measurable impact from day one.

From end-of-line inspection to in-process error proofing, traceability, and human-machine collaboration, Hypervise is your partner in building intelligent, future-ready factories.

Ready to see the future of manufacturing through the eyes of AI? Explore our case studies or schedule a live demo to experience Hypervise in action.