Key Takeaways

- Profit Killer: False rejects involve discarding perfectly functional parts, which directly erodes profit margins and increases material waste.

- Root Causes: Traditional cameras fail due to environmental factors such as glare from overhead factory lights, vibrations, or harmless oil residue on metal surfaces.

- The Solution: Transitioning from rule-based logic to Deep Learning allows systems to “see” like a human, effectively distinguishing between dirt and real defects.

- Hypervise Advantage: Advanced AI tools adapt to changing lighting and surface textures without constant reprogramming.

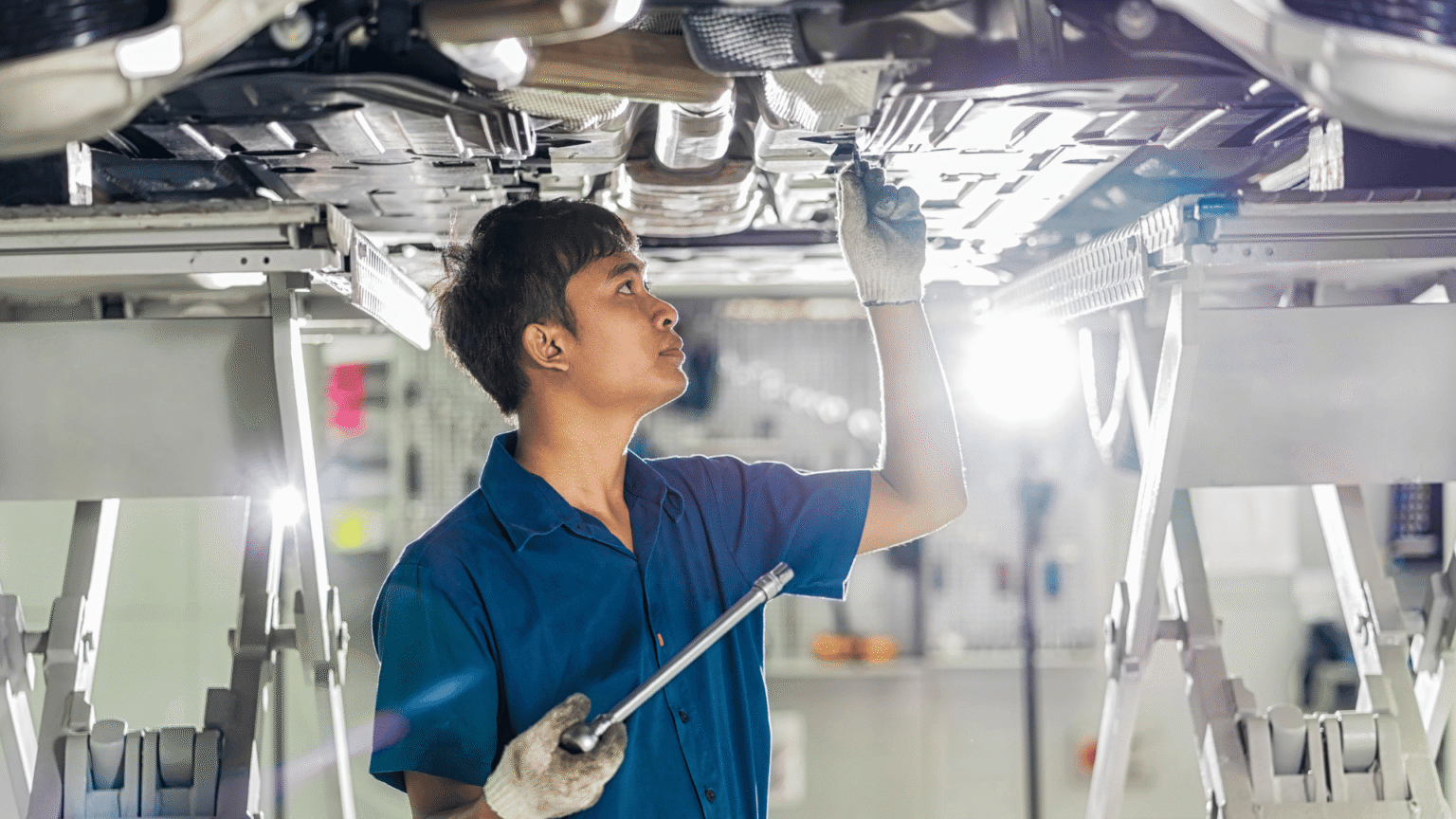

In the high-stakes world of automotive manufacturing, where production lines move at breakneck speeds and precision is non-negotiable, the accumulation of “scrap” that is actually compliant product represents a massive, often overlooked financial drain. Manufacturers are increasingly prioritising False Rejection Rate Reduction as a critical KPI, realising that throwing away good parts due to overly sensitive or unintelligent sensors is just as damaging to the bottom line as shipping a defective product. While Automated Defect Detection has transformed the industry, reliance on outdated optical technologies continues to generate false positives that stall production and waste valuable materials.

What is False Rejection Rate Reduction?

False Rejection Rate Reduction is the systematic optimisation of quality control processes to minimise the frequency with which acceptable products are incorrectly identified as defective by automated inspection systems.

In automotive manufacturing, this means upgrading from rigid, rule-based machine vision to adaptive deep learning models that can accurately differentiate between cosmetic anomalies—such as harmless oil spots or watermarks—and genuine structural flaws, thereby maximising yield without compromising safety standards.

The Pain Point: Why Good Parts End Up in the Bin

Anyone who has spent time on a real factory floor knows that the manufacturing environment is far from a sterile laboratory. It is a dynamic, messy ecosystem filled with variables that confuse standard cameras. The primary driver for aggressive False Rejection Rate Reduction is the inability of legacy systems to cope with real-world conditions, such as metal stamping and assembly environments where parts are often covered in oil residue or dust that looks like a scratch to a basic sensor.

Additionally, intense glare from overhead factory lights reflecting off shiny machined surfaces creates “hot spots” that rule-based algorithms misinterpret as cracks or voids. This leads to the immediate rejection of perfectly flawless engine blocks or chassis components.

The Cause: The Failure of Rule-Based Cameras

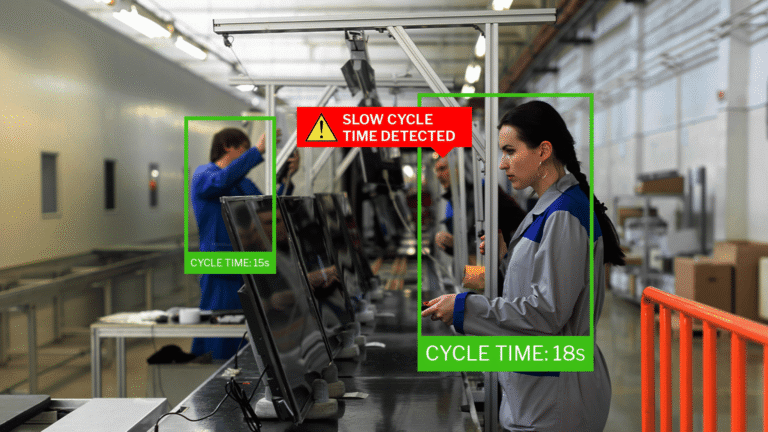

The industry has long relied on rule-based machine vision systems that operate on binary “pass/fail” logic defined by strict, pre-programmed parameters. These systems struggle because they lack contextual understanding.

If a pixel value crosses a certain threshold due to a lighting change or a vibration affecting the camera mount, the part is rejected. This rigidity is the opposite of effective automotive quality control, as it demands constant manual recalibration whenever factory conditions shift, resulting in high maintenance costs and persistently high false rejection rates.

The Fix: Deep Learning and Hypervise Vision AI

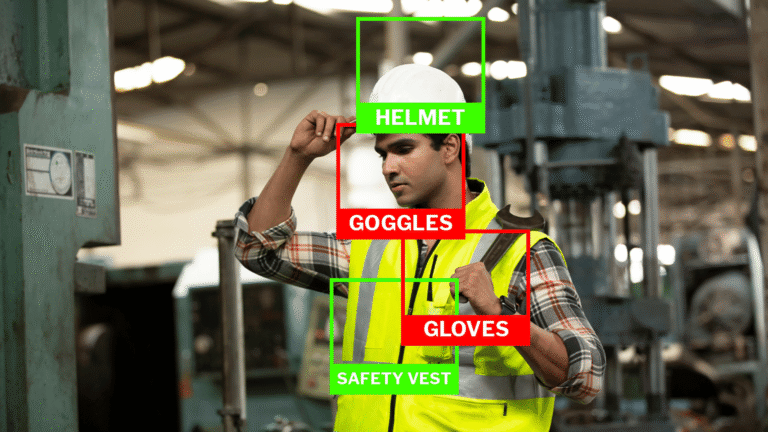

To achieve meaningful False Rejection Rate Reduction, manufacturers are turning to deep learning technologies such as Hypervise Vision AI, which fundamentally differ from traditional approaches by mimicking the way the human eye and brain interpret visual information.

Unlike rule-based systems that look for specific pixel arrangements, Hypervise is trained on thousands of images of both good and defective parts. This allows it to learn what a real defect looks like versus a harmless environmental anomaly.

As a result, the system can ignore glare on a bumper or lubricant on a piston and focus only on deviations that truly impact quality.

Comparison: Rule-Based vs. Deep Learning Vision Systems

The following table outlines why shifting to AI-driven solutions is essential for reducing false rejects.

| Feature | Traditional Rule-Based Vision | Deep Learning (Hypervise) |

| Detection Logic | Rigid, pre-defined rules (if X, then Y) | Adaptive learning based on examples |

| Environmental Sensitivity | High failure rate with lighting changes or glare | Robust against lighting shifts and reflections |

| Surface Handling | Confused by oil, dust, or watermarks | Can ignore harmless surface residues |

| Setup Complexity | Requires complex programming for every variant | Requires image training sets (faster deployment) |

| False Rejection Rate | High (typically 5–10%) | Extremely low (<0.5%) |

Steps to Implement False Rejection Rate Reduction

Implementing a modern vision system requires a strategic approach to ensure smooth integration with existing production lines.

- Audit Current Reject Stations:

Analyse scrap bins to determine what percentage of rejected parts are actually good, and identify environmental triggers such as lighting angles or reflections that cause errors. - Gather Image Data:

Instead of writing complex code, collect a dataset of images showing both real defects and “pseudo-defects” (oil, glare, dust) that confuse your current system. - Deploy Hypervise Vision AI:

Use deep learning models that ingest this data and train themselves to distinguish between real defects and harmless anomalies with high precision. - Continuous Training:

As new defects appear, feed those images back into the system to continuously refine and improve accuracy.

For manufacturers ready to stop throwing away profit and start utilising the full power of AI-driven inspection, seeing Hypervise in action is the best way to understand how it adapts to complex factory environments.

Frequently Asked Questions

Reducing false rejects directly improves Overall Equipment Effectiveness (OEE) by increasing the Quality score. It ensures that production time results in saleable inventory rather than waste, boosting overall line efficiency.

Yes. Deep learning systems like Hypervise are specifically designed to handle challenging surfaces. They learn to ignore variations caused by halation and reflections that typically trigger false rejects in traditional rule-based cameras.

While it involves a technological shift, modern AI vision platforms are designed for ease of use. They often require less programming knowledge because they learn from image examples rather than complex rule-based logic.

While zero is the ideal target, world-class manufacturing standards typically aim for a False Rejection Rate (FRR) of less than 0.5%. Legacy systems often struggle to keep FRR below 3–5% without allowing actual defects to pass.