In the high-stakes world of modern manufacturing, the margin for error has effectively vanished. While production lines strive for efficiency, the ultimate metric of success remains the quality of the final output delivered to the customer. However, even the most rigorous manual protocols often fail to catch every anomaly, leading to what industry experts term a “defect escape.” This occurs when a non-conforming or faulty part slips through the quality control net and reaches the customer, triggering a cascade of financial and reputational consequences. Implementing a robust defect detection system is no longer just a technical upgrade; it is a critical strategic imperative for survival.

Key Takeaways

- Defect escapes occur when faulty products reach the customer, often causing severe brand damage and recalls.

- The 1-10-100 Rule illustrates that the cost of fixing a defect increases exponentially the later it is detected.

- Human inspection is fallible due to fatigue, whereas automated systems provide 100% inspection coverage at machine speed.

- Advanced defect detection systems like Hypervise are essential for achieving Zero Defect Manufacturing.

What Is a Defect Detection System?

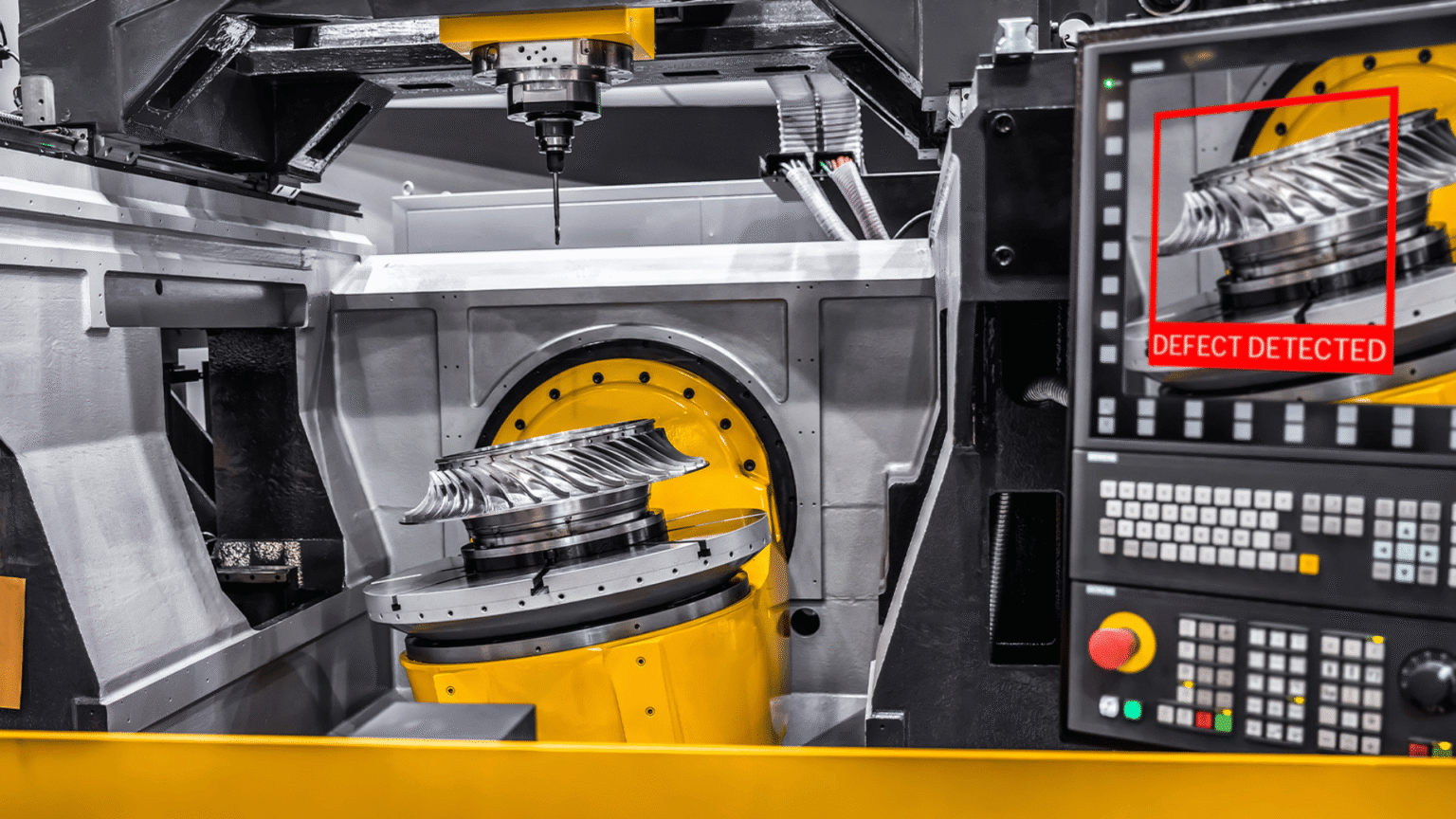

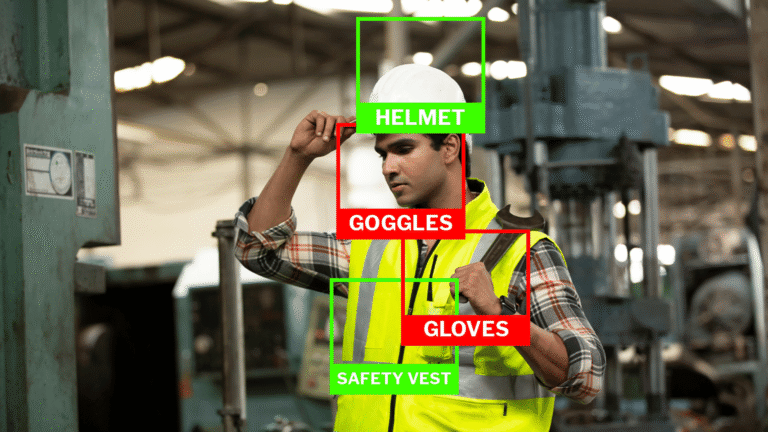

A defect detection system is an automated quality control solution that utilises advanced technologies—such as computer vision, machine learning algorithms, and high-resolution sensors—to identify surface or structural anomalies in manufactured goods. Unlike manual inspection, which relies on human judgement, these systems continuously monitor production lines to detect deviations from standard specifications, ensuring that defective parts are identified and rejected before they proceed to the next stage of the supply chain.

The Reality of Defect Escapes: Why Humans Miss Errors

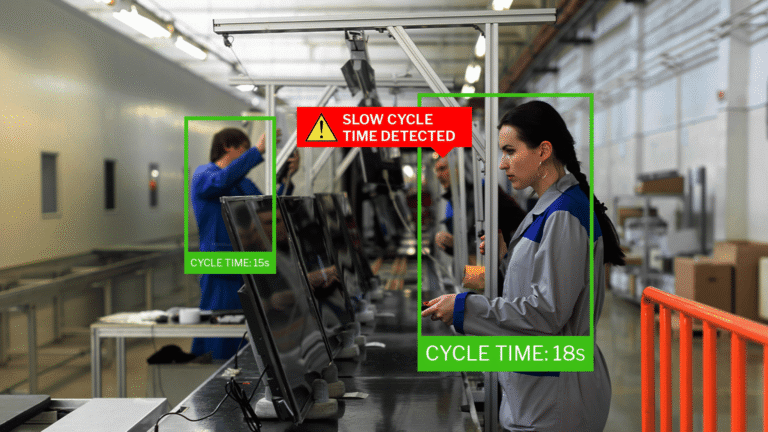

The concept of a defect escape is a nightmare scenario for any production manager. It represents a failure in the containment process, where a sub-standard unit leaves the factory floor. The harsh reality of manufacturing is that 100% human inspection is practically impossible to sustain over long shifts. Humans are biologically prone to fatigue, distraction, and cognitive drift, meaning that even the most diligent inspector will eventually miss a scratch, a misalignment, or a missing component.

When a defect escapes, the impact is far greater than a single returned item. It often leads to significant brand damage, expensive product recalls, and the potential loss of lucrative long-term contracts.

The Economic Impact: The 1-10-100 Rule

To understand the financial gravity of implementing a defect detection system, consider the 1-10-100 Rule of quality costs. This industry-standard concept quantifies the exponential increase in the Cost of Poor Quality (COPQ) based on when a defect is detected.

- $1 (Prevention): Detecting and fixing a defect during the design or initial setup phase costs a nominal amount. This is the ideal scenario, where issues are resolved before production begins.

- $10 (Correction): If a defect is detected during production or internal inspection, the cost to rework or scrap the part rises significantly. Although wasteful, the issue remains contained within the factory.

- $100 (Failure): If the defect escapes and reaches the customer, the cost multiplies dramatically. This includes warranty claims, return logistics, legal liabilities, and the intangible but devastating erosion of customer trust.

By relying solely on manual inspection, manufacturers are effectively gambling against this $100 penalty using processes that are inherently prone to error. The only reliable way to avoid this cost is to ensure defects never leave the facility.

The Solution: Hypervise and 100% Inspection Coverage

Eliminating defect escapes requires a transition from sampling and manual checks to automated supervision. Technologies like Hypervise deliver 100% inspection coverage at machine speed—something human workforces cannot achieve.

By deploying an advanced defect detection system, manufacturers can inspect every unit that passes through the production line instead of relying on statistical sampling, which always leaves room for error. This level of scrutiny transforms Zero Defect Manufacturing from a theoretical objective into an operational reality.

Comparing Human Inspection vs. Automated Defect Detection

The following table outlines why shifting to automated systems is critical for recall prevention and cost management.

| Feature | Human Inspection | Automated Defect Detection System |

| Consistency | Variable (affected by mood, fatigue, health) | 100% consistent (standardised algorithms) |

| Speed | Slow, often creates bottlenecks | Matches or exceeds production line speed |

| Data Traceability | Low (manual logging required) | High (automatic digital image logging) |

| Detection Rate | 80–90% effective on average | Near 100% accuracy with proper calibration |

| Long-Term Cost | High (recurring salaries, training) | Low (initial investment, minimal maintenance) |

Implementing Recall Prevention Strategies

Integrating a defect detection system is one of the most effective forms of recall prevention. When a system can identify deviations as small as a micron, it stops the “snowball effect” of quality failures before they escalate.

Additionally, these systems generate rich analytical data that helps engineers identify root causes—such as tool wear, machine misalignment, or raw material inconsistencies—and correct them immediately. For manufacturers looking to protect both their reputation and their profitability, upgrading is no longer optional; it is essential.

Frequently Asked Questions

Its primary function is to automatically inspect products during manufacturing and reject defective items before they reach the customer, thereby minimising the risk of defect escapes.

The rule shows that investing at the $1 or $10 stage is far cheaper than absorbing the $100 cost when defects reach customers, making automation financially compelling.

While perfection is theoretical, advanced defect detection systems bring manufacturers as close as possible by inspecting 100% of parts rather than relying on random sampling.

Modern systems can identify cosmetic flaws (scratches, dents), structural issues (cracks, porosity), assembly errors (missing parts, misalignment), and dimensional inaccuracies.