In the rapidly evolving manufacturing landscape, the debate between maintaining traditional workforce methods and adopting advanced automation is no longer just about technology; it is fundamentally about economics. As we move into 2026, understanding the AI Visual Inspection Cost is critical for plant managers and CFOs who are tasked with optimising production lines without sacrificing quality. While the initial sticker price of automated systems may seem daunting compared to a monthly payroll, a deeper dive into the data reveals a stark difference in long-term value, efficiency, and scalability.

Key Takeaways

- Accuracy Gap: Human inspection typically caps at 80–85% accuracy due to fatigue, whereas AI systems consistently achieve 99%+.

- Cost Structure: Manual inspection involves variable and rising operational costs; AI represents a fixed capital cost with minimal maintenance.

- ROI Timeline: Most manufacturers see a return on investment within 8 to 12 months of implementation.

- Hidden Costs: The “Cost of Quality” (returns, scrap, rework) is significantly lower with Automated Optical Inspection.

What Is AI Visual Inspection Cost?

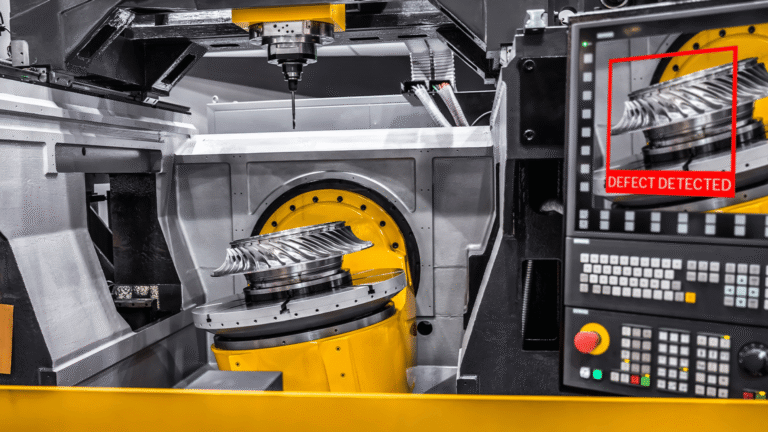

AI Visual Inspection Cost refers to the total capital and operational expenditure required to implement computer vision systems for quality control. This includes the initial hardware investment (cameras, lighting, processing units), software licensing or development fees, and integration services.

Unlike manual inspection, which incurs continuous variable costs through wages and overtime, AI inspection transforms quality control into a predictable, fixed-cost asset that depreciates over time while increasing in efficiency.

Human Inspectors vs. AI: The Efficiency Gap

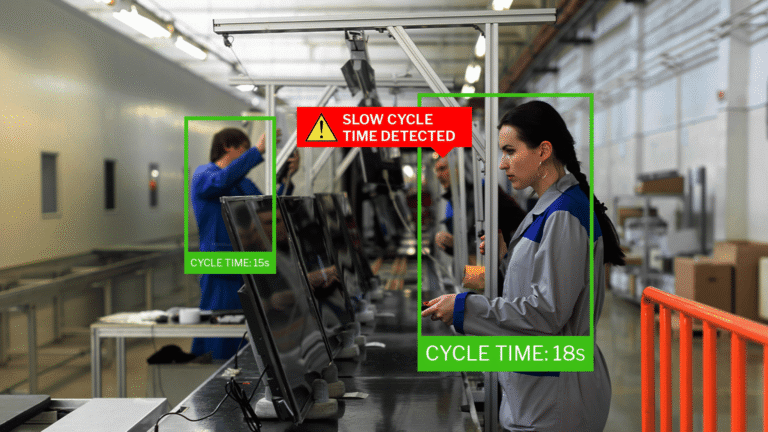

When evaluating the financial implications of quality control, it is essential to compare the inherent limitations of biological operators with the capabilities of silicon-based systems. Human inspectors are incredibly versatile but suffer from physiological constraints that directly impact the bottom line. Fatigue is unavoidable; studies consistently show that after just two hours of repetitive tasks, human attention spans degrade significantly, leading to an accuracy ceiling of approximately 80%.

Furthermore, reliance on human labour introduces expensive variables such as overtime pay during peak seasons, training costs due to high turnover, and liabilities related to workplace ergonomics.

Conversely, AI-driven systems operate on a fundamentally different economic model. An AI system functions 24/7 without any drop in performance, maintaining a 99% accuracy rate whether it is the first minute of the shift or the last. The cost associated with AI is largely upfront, followed by nominal maintenance fees, whereas human labour costs compound annually with inflation and wage increases. Below is a structured comparison of the operational differences.

| Feature | Manual Inspection (Human) | AI Visual Inspection (Automated) |

| Accuracy Rate | ~80–85% (declines with shift duration) | 99%+ (consistent 24/7) |

| Operational Availability | 8–10 hours/shift (requires breaks) | 24 hours/day (no breaks required) |

| Cost Type | Variable (wages, overtime, benefits) | Fixed (upfront CapEx + low OpEx) |

| Scalability | Linear (hire more people to scale) | Exponential (replicate software across new lines) |

| Data Insights | Subjective / manual logging | Real-time, actionable analytics |

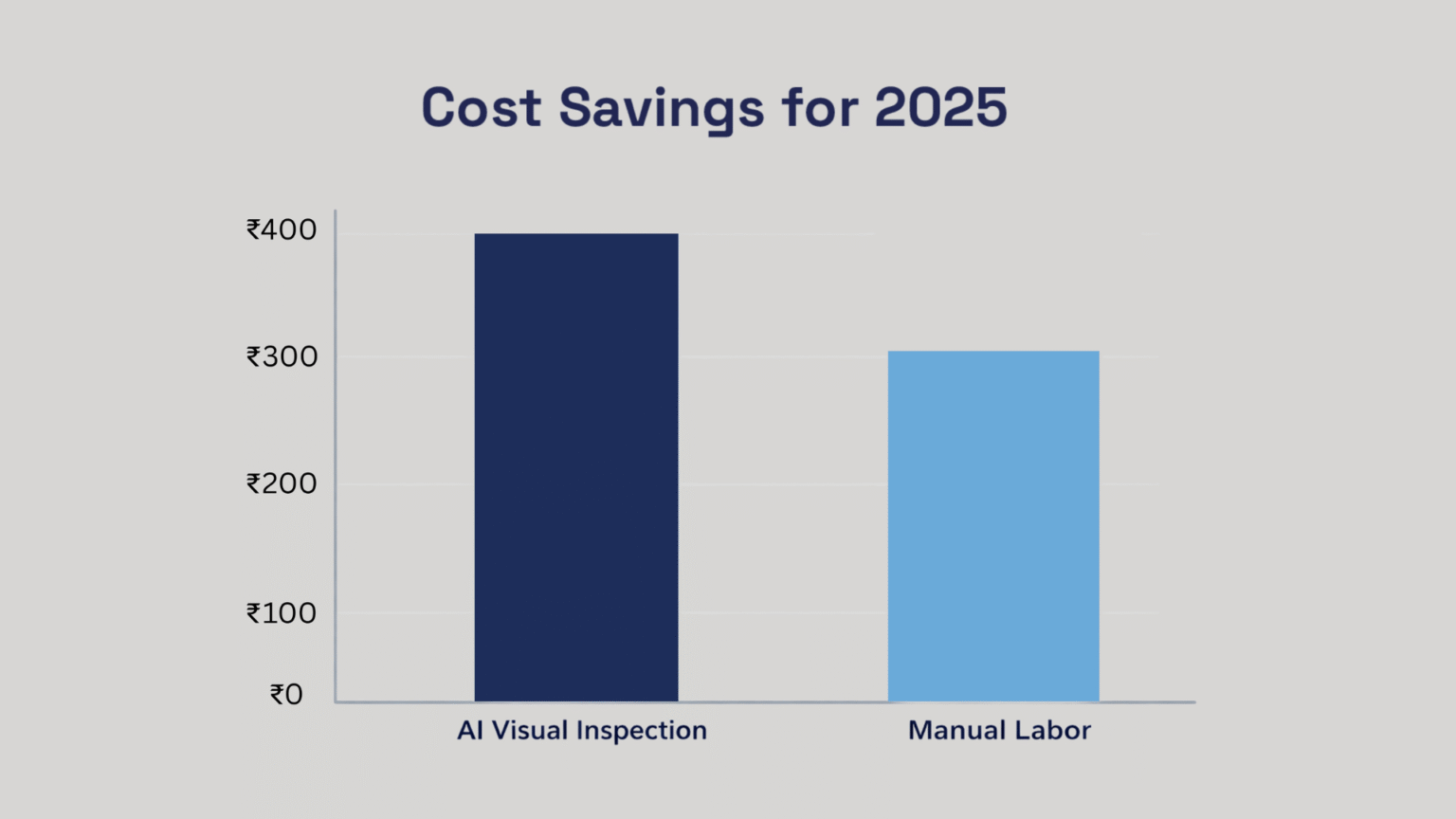

The Math: Calculating the ROI

To truly understand the benefits of AI Visual Inspection Cost, consider a hypothetical yet realistic manufacturing scenario. Assume you are running a production facility that operates continuously to meet market demand. You require coverage for three shifts per day, and the production volume requires four inspectors per shift to keep up with conveyor speed.

Scenario: 3 Shifts, 4 Inspectors per Shift

In this manual model, you employ 12 staff members dedicated solely to visual inspection. Assuming a modest fully burdened labour cost (wages, taxes, insurance, benefits) of $45,000 per inspector per year:

- Inspectors: 12 employees

- Cost per Employee: $45,000 per year

- Total Annual Manual Cost: $540,000

This $540,000 is a recurring expense that will likely increase each year due to wage inflation. This figure also excludes the cost of escapes (defective products reaching customers) caused by the inherent 15–20% error rate of manual inspection.

The Hypervise AI Solution

Now compare this to implementing a system like Hypervise. While exact costs vary based on complexity, a robust AI deployment for a similar line might involve a one-time hardware setup fee and an annual software subscription.

- Initial Hardware & Integration: $80,000 (one-time CapEx)

- Annual Software & Support: $40,000 (recurring OpEx)

- Total First-Year Cost: $120,000

The Savings:

In the first year alone, you save $420,000 ($540,000 – $120,000). In subsequent years, when you only pay the software and maintenance fees, your savings increase to approximately $500,000 annually.

This dramatic reduction in overhead allows you to reallocate human workers to higher-value tasks that require critical thinking rather than repetitive observation. For a personalised ROI breakdown specific to your production line, a demo can provide precise projections.

Hidden Expenses: The Cost of Quality

When analysing manual inspection ROI, many manufacturers overlook the “Cost of Quality.” This includes expenses related to:

- Internal failures: Scrap, rework

- External failures: Returns, warranty claims, brand damage

Because manual inspection allows approximately 15–20% of defects to slip through, the cost of quality remains artificially high. Automated Optical Inspection (AOI) drastically reduces these escapes.

For example, if your facility produces 1,000,000 units per year and the cost of a return is $50, a mere 1% reduction in defect escapes saves $500,000 directly. AI systems, with their ability to detect microscopic flaws invisible to the human eye, often reduce defect escape rates to near zero—effectively paying for themselves through quality assurance alone.

The Verdict: When Does AI Pay for Itself?

Based on the calculations above, the financial argument is overwhelming. For most high-volume manufacturers, the break-even point—where investment in AI equals the cost of manual labour—occurs within 8 to 12 months. After this period, the system generates pure profit in the form of cost savings.

By 2026, relying on manual visual inspection will not merely be inefficient; it will be a competitive disadvantage that drains resources and limits scalability.

Note: All costs, savings, and ROI figures mentioned above are purely indicative and for illustrative purposes only. Actual numbers may vary depending on production volume, line complexity, regional labour costs, system configuration, and integration requirements. A detailed assessment is recommended to arrive at precise financial projections for your specific manufacturing setup.

Frequently Asked Questions

The cost varies significantly based on complexity, but a standard single-line deployment typically ranges from $50,000 to $150,000 for the initial setup, including hardware and software integration. This is often less than the annual cost of employing two full-time human inspectors.

Most facilities operating multiple shifts achieve a full Return on Investment (ROI) within 8 to 12 months. Facilities with high scrap rates or expensive product returns may see an ROI in as little as 6 months due to the significant reduction in the Cost of Quality.

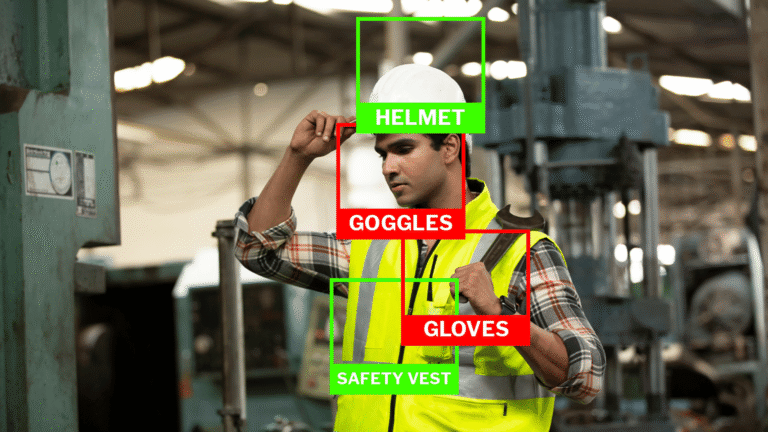

AI is designed to replace the repetitive, high-speed task of defect detection. However, humans are still essential for supervising the system, handling complex anomalies that the AI has not encountered before, and managing the overall quality assurance process. The goal is augmentation and efficiency, not the complete replacement of the workforce.