In the industrial sector, the mere mention of cameras often triggers immediate resistance among the workforce, evoking a deep-seated fear of “Big Brother” surveillance where every move is scrutinized for the sole purpose of punishment. However, the landscape of SOP Compliance Monitoring is undergoing a radical transformation that prioritizes skill acquisition over punitive oversight. By leveraging advanced computer vision, manufacturers are shifting the dynamic from catching workers doing something wrong to helping them do it right in real-time. We believe in empowering the operator, ensuring that technology serves as a digital assistant rather than a relentless overseer.

Key Takeaways

- Shift in Perspective: Modern monitoring moves away from surveillance and toward real-time assistance.

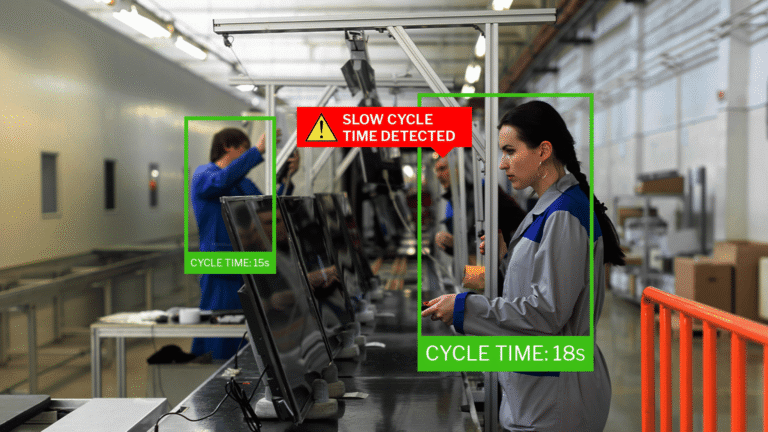

- Instant Feedback: AI flags errors immediately, allowing workers to correct mistakes before the product moves down the line.

- Accelerated Learning: Visual guidance systems can increase training speed for new employees by up to 2x.

- Ethical Operations: The goal is empowering the operator through Action Recognition Software, not replacing them.

What is SOP Compliance Monitoring?

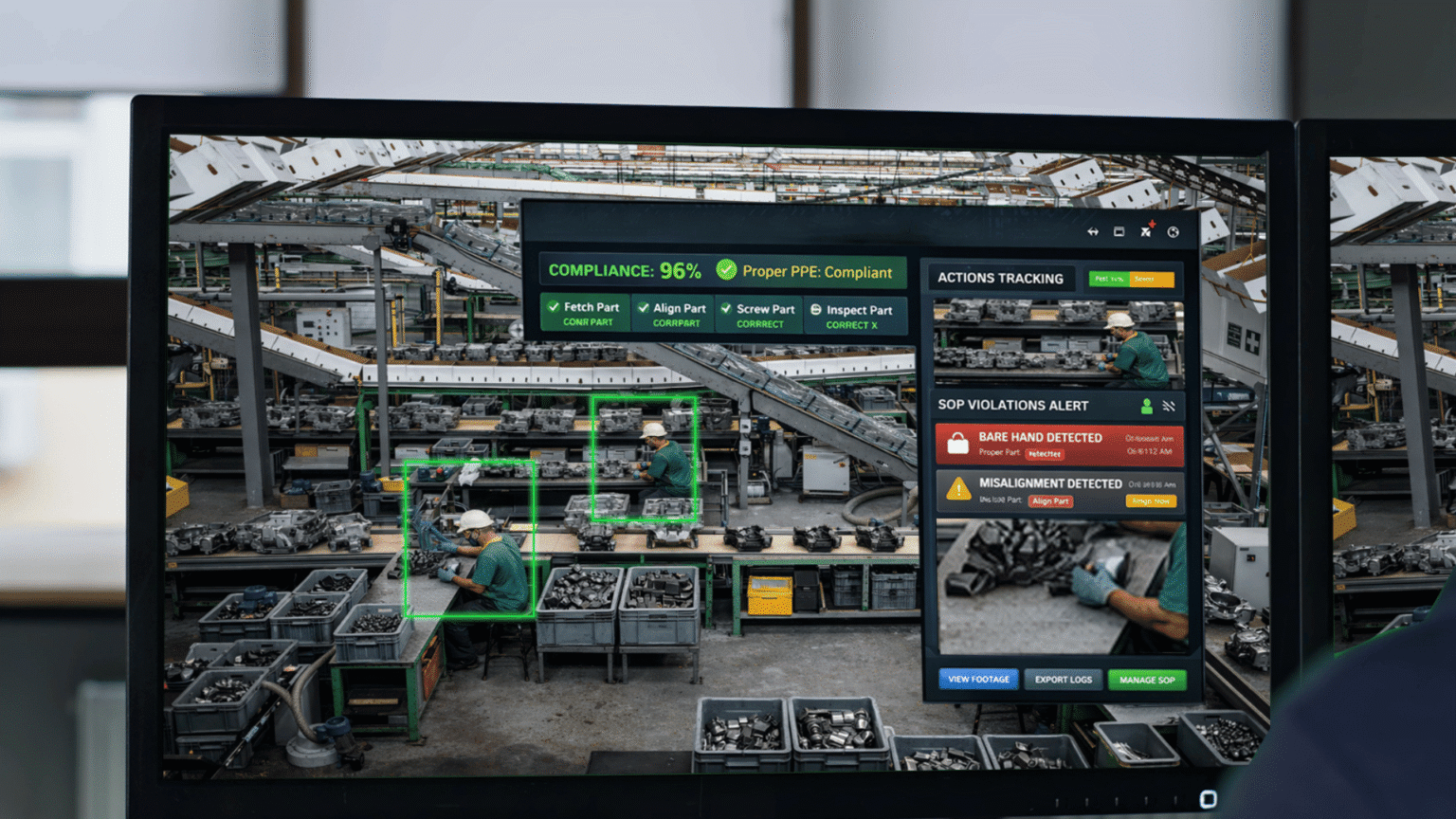

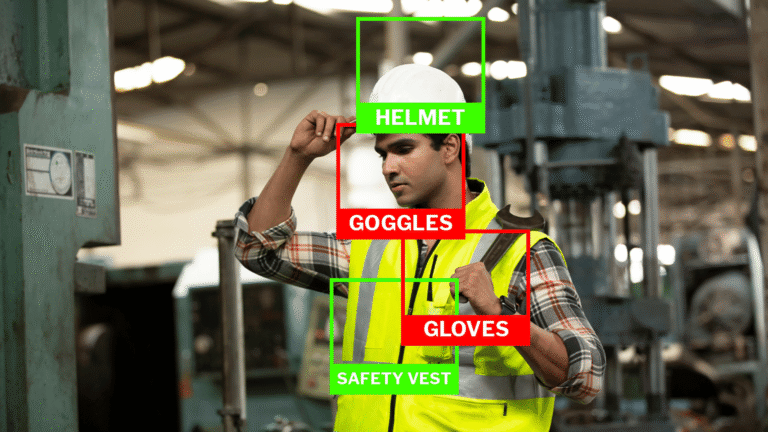

SOP Compliance Monitoring is the systematic process of tracking, analyzing, and verifying that operational activities strictly adhere to established Standard Operating Procedures (SOPs). In modern manufacturing, this definition has evolved to include the use of computer vision and AI technologies that automatically detect deviations from standardized workflows in real-time, providing immediate data to ensure consistency, safety, and quality control without requiring constant human supervision.

The Fear vs. The Shift: Redefining Monitoring

Traditionally, compliance audits were retrospective and punitive; a manager would review footage hours or days after an incident, leading to disciplinary action for the worker involved. This approach naturally breeds resentment and anxiety, as employees feel they are walking on eggshells. The introduction of platforms like Hypervise changes this dynamic fundamentally by turning the camera into a proactive support tool. Instead of punishing a worker for a mistake discovered later, the AI identifies the deviation—such as a missed bolt or an improper assembly sequence—and flags it in real-time so the operator can fix it immediately. This ensures that the product is perfect before it moves down the line, saving the company money on rework while saving the worker from the stress of a formal reprimand.

The Benefit: An Instant Training Tool

Beyond quality assurance, this technology functions as a powerful engine for Worker Training AI. When new employees join the production line, the learning curve is often steep and stressful, but computer vision acts as an always-on digital coach that guides their hands. Because the system provides instant visual feedback when a step is missed or performed incorrectly, new hires can self-correct and internalize the process much faster than they would with manual shadowing alone. Industry data suggests that new employees learn 2x faster because the AI guides them through the nuance of Standard Operating Procedures, effectively bridging the skills gap with technology.

Furthermore, this approach aligns with broader safety goals. By ensuring protocols are followed precisely, companies can mitigate risks significantly. For a deeper dive into how vision systems protect workers, read about how AI vision transforms industrial safety.

Comparing Monitoring Approaches

To understand the value of AI-driven SOP Compliance Monitoring, it is helpful to compare it directly against traditional manual auditing methods.

| Feature | Traditional Manual Audits | AI Computer Vision (Hypervise) |

| Timing of Feedback | Delayed (Post-shift or Post-incident) | Real-time (Instant correction) |

| Worker Perception | “Big Brother” / Punitive | Digital Assistant / Supportive |

| Training Impact | Low (Reactive coaching) | High (Proactive, continuous guidance) |

| Data Accuracy | Subjective / Sample-based | Objective / 100% Coverage |

| Scalability | Limited by human manager availability | Infinite (Scales across all lines instantly) |

How Action Recognition Software Works

The technology underpinning this shift is known as Action Recognition Software, which breaks down complex human movements into analyzable data points. The process generally follows these steps:

- Skeletal Tracking: The system maps the worker’s joints and movements to understand their posture and reach.

- Object Detection: It identifies the tools and parts being used in the assembly process.

- Sequence Analysis: The AI compares the observed actions against the digital SOP to ensure the correct order of operations.

- Deviation Alerting: If a step is skipped, the system alerts the operator via a screen or light, prompting a correction.

We believe in empowering the operator, and this technology provides them with the autonomy to master their craft without fear of failure. If you are ready to transform your training and compliance workflows, schedule a demo today.

Frequently Asked Questions

The primary goal is to ensure consistency and quality by detecting deviations from Standard Operating Procedures in real-time. Unlike traditional methods, AI monitoring focuses on immediate correction and worker support rather than retrospective punishment.

It shifts the focus from surveillance to support. By providing immediate feedback that allows a worker to fix a mistake before it becomes a recorded error, the system acts as a tool for success rather than a mechanism for disciplinary action.

No, it is designed to augment human trainers, not replace them. The software handles the repetitive, minute-by-minute guidance on the line, allowing human trainers to focus on high-level strategy, soft skills, and complex problem-solving.

While there is an initial investment in hardware and software, the return on investment is often realized quickly through reduced scrap rates, faster onboarding of new employees (up to 2x speed), and the prevention of costly safety incidents.