Key Takeaways

- Human-Centricity: Industry 5.0 solutions shift the focus from pure automation to empowering human workers with advanced technology.

- The Missing Link: Action Recognition serves as the critical bridge, allowing AI to understand and assist human movements in real-time.

- Hypervise AI: Advanced computer vision tools act as intelligent coaches rather than passive surveillance systems, enhancing safety and quality.

There is a pervasive myth circulating through boardrooms and factory floors that the next phase of industrial evolution is simply about deploying more robots to replace the remaining human workforce. However, this perspective fundamentally misunderstands the core philosophy behind emerging Industry 5.0 solutions, which define the future not as machines replacing people, but as humans and AI working together in a seamless, symbiotic partnership. While the previous industrial revolution prioritized cold efficiency and data exchange, this new era recognizes that the flexibility, creativity, and problem-solving capabilities of the human worker are irreplaceable assets that must be augmented, not eliminated.

What are Industry 5.0 Solutions?

Industry 5.0 solutions encompass a sophisticated suite of technologies designed to reintegrate human agency into the manufacturing process by pairing the precision of advanced automation with the cognitive skills of human workers. Unlike Industry 4.0, which focused heavily on interconnectivity and smart automation, Industry 5.0 prioritizes human-centric manufacturing, sustainability, and resilience, utilizing collaborative robots (cobots) and AI-driven analytics to create a personalized, interactive, and highly efficient production environment.

The Problem: Why Industry 4.0 Left Workers Behind

The Fourth Industrial Revolution was undoubtedly a technological marvel that connected machines and generated unprecedented amounts of data, yet it ultimately failed to address the needs of the most critical variable on the factory floor: the human worker. In the race toward total automation, systems were designed to extract data from machines while ignoring the physiological and cognitive states of the people operating them, creating a disconnect where workers felt alienated rather than empowered. Manufacturers found themselves drowning in sensor data that described machine health but offered zero insight into why a skilled operator made a mistake or how fatigue was impacting production quality. By ignoring the principles of human-robot collaboration, Industry 4.0 created a sterile environment where humans were treated as potential sources of error rather than the architects of value.

The Solution: Action Recognition as the Ultimate Coach

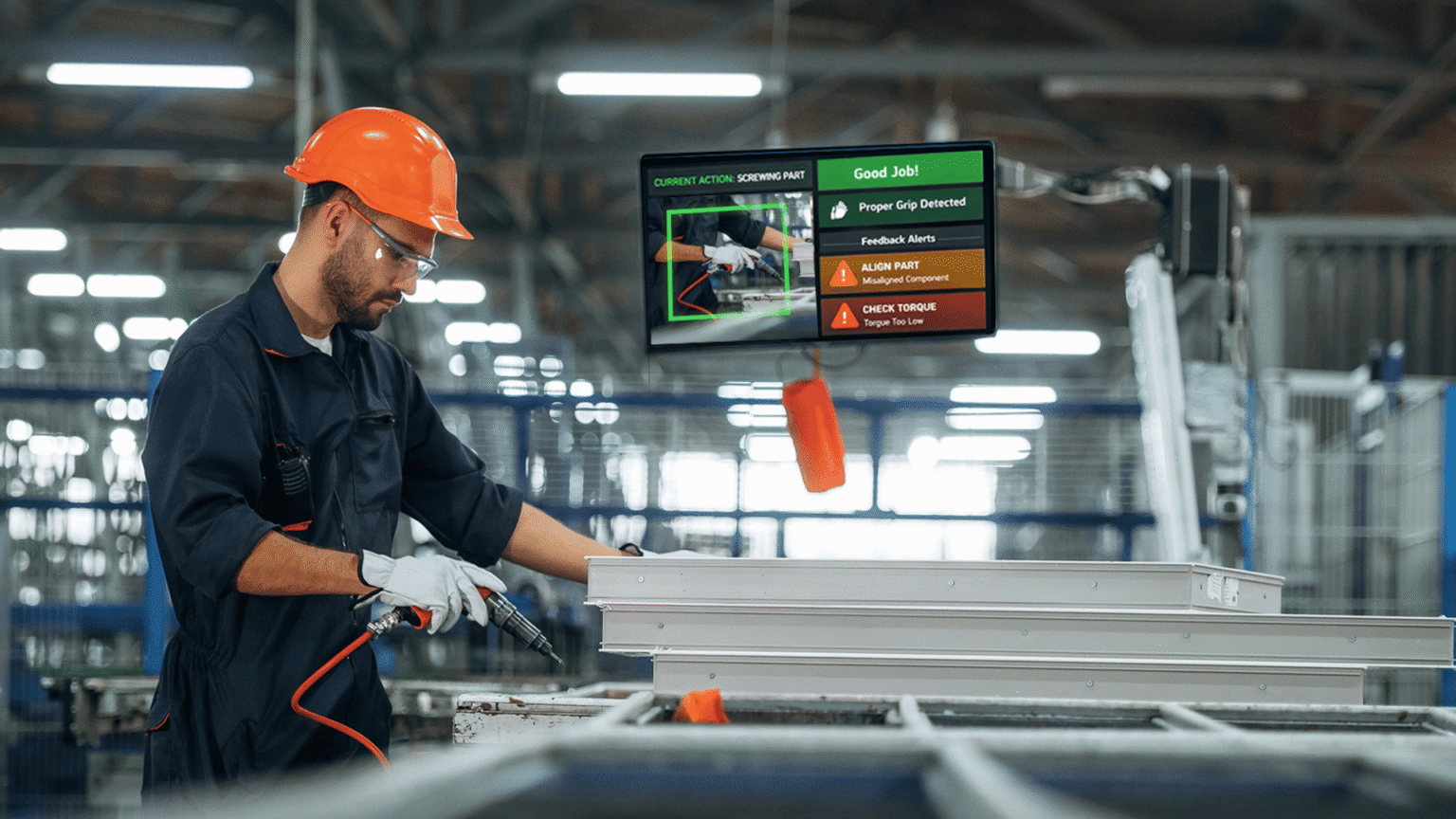

To bridge the gap between digital intelligence and human dexterity, forward-thinking manufacturers are turning to Action Recognition technology, a cornerstone of modern Industry 5.0 solutions. This technology, exemplified by platforms like Hypervise AI, utilizes advanced computer vision to observe human workers in real-time, but with a distinct and revolutionary purpose: it acts as a coach rather than a warden. Instead of merely recording footage for surveillance, these systems analyze complex movement patterns to provide immediate, constructive feedback, much like a sports coach correcting an athlete’s form to prevent injury and improve performance.

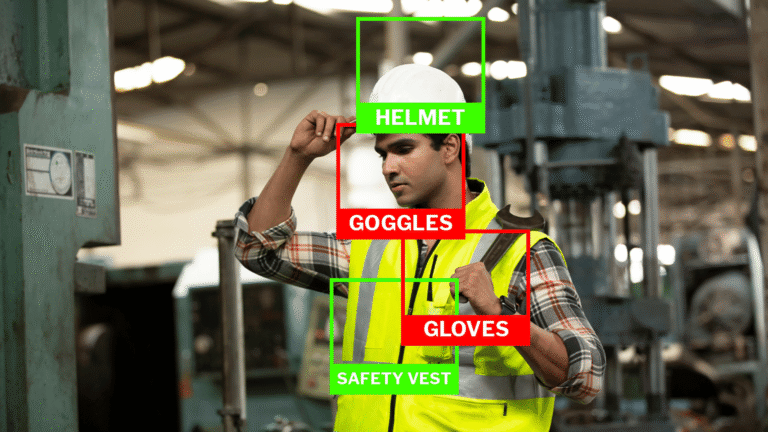

By leveraging Action Recognition, Hypervise AI can detect when a worker is performing a task with non-ergonomic posture or deviating from standard operating procedures, subsequently offering guidance that enhances safety and efficiency. This approach transforms the camera from a passive recording device into an active partner in human-centric manufacturing, ensuring that the technology serves the worker. For those interested in how these concepts are being applied in specific emerging markets, you can read more about what is Industry 5.0 in manufacturing India to understand the global scale of this transition.

Comparing Industry 4.0 and Industry 5.0

The following table illustrates the fundamental shifts in priority and technology between the two industrial paradigms, highlighting why Industry 5.0 solutions are necessary for the future workforce.

| Feature | Industry 4.0 | Industry 5.0 |

| Primary Focus | Automation and Efficiency | Human-Centricity and Sustainability |

| Role of the Human | Supervisor or Operator (often replaced) | Collaborator and Creative Lead |

| Key Technology | IoT, Big Data, Cloud Computing | Collaborative Robots (Cobots), Hypervise AI, Action Recognition |

| Goal | Mass Customization via Automation | Hyper-Personalization via Human-Robot Collaboration |

| Interaction Type | Man vs. Machine | Man with Machine |

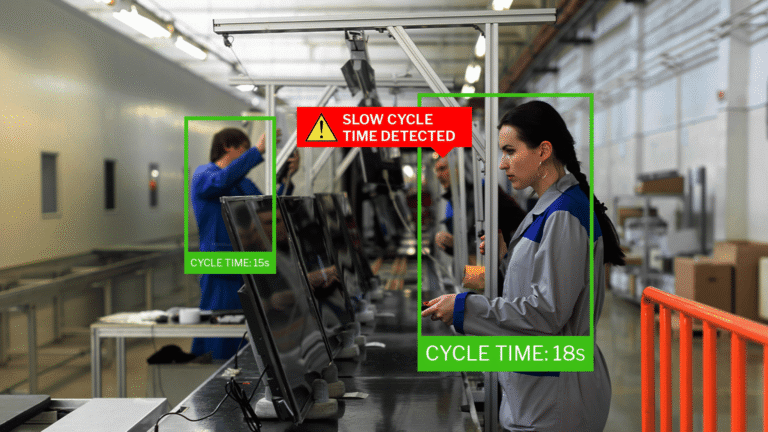

Why Human-Robot Collaboration Matters Now

Implementing Industry 5.0 solutions is not merely a philosophical choice but a strategic imperative for manufacturers facing labor shortages and increasing demands for customization. Human-robot collaboration allows factories to handle high-mix, low-volume production runs that fully automated lines struggle to manage efficiently. By equipping workers with AI tools that understand intent and action, companies can reduce training times, virtually eliminate assembly errors, and foster a workplace culture where technology enhances job satisfaction. If you are ready to see how Action Recognition can transform your shop floor into a smart, human-centric environment, you should book a demo today to witness the future of manufacturing.

Frequently Asked Questions

While Industry 4.0 focused on the interconnectivity of machines and system automation to minimize human intervention, Industry 5.0 solutions prioritize the collaboration between humans and machines, aiming to combine the creativity of craftsmanship with the speed and efficiency of industrial automation.

Hypervise AI supports human-centric manufacturing by using Action Recognition to monitor worker safety and ergonomics in real-time, providing feedback that prevents injuries and defects without replacing the worker, thereby acting as an intelligent assistant rather than a replacement.

No, Industry 5.0 is not about adding more autonomous robots; it is fundamentally about implementing collaborative robots (cobots) and AI systems that work alongside humans to enhance their capabilities, ensuring that the manufacturing process remains resilient, sustainable, and human-focused.

Action Recognition technology provides granular visibility into manual processes, allowing manufacturers to standardize best practices, improve ergonomic safety, ensure quality control during assembly, and facilitate seamless human-robot collaboration by enabling machines to understand human movements.