In complex industrial environments, safety isn’t optional—it’s mission critical. For Health, Safety, and Environment (HSE) leaders, the responsibility is relentless. Every shift carries the same questions:

- Can we prevent accidents before they happen?

- Are safety measures genuinely effective—or only assumed to be?

- If regulators ask tomorrow, do we have the data to prove compliance?

- What unseen risks could be putting workers and operations at risk right now?

AI Vision offers an answer. By moving from reactive safety management to predictive prevention, organizations gain real-time visibility into risks and can take immediate action to protect workers and ensure operational resilience.

Why Incident Prevention Must Come First

The data underscores just how serious the problem is:

- Globally, 2.78 million workers lose their lives every year due to workplace accidents or occupational diseases (ILO).

- Over 374 million suffer non-fatal work-related injuries.

- In the US alone, workplace injuries cost businesses more than $167 billion annually (NSC).

Beyond the financial burden, accidents disrupt operations, invite regulatory scrutiny, and damage trust with employees and stakeholders. That’s why proactive incident prevention is the most cost-effective safety strategy available to industrial leaders.

Four Ways AI Vision Reduces Risk and Prevents Incidents

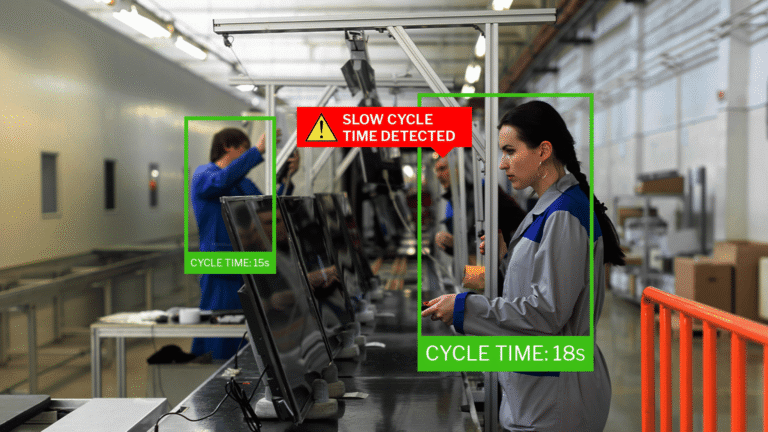

AI Vision uses real-time video analytics to continuously monitor operations, detect hazards, and generate actionable safety insights. Here are four high-impact applications:

1. Forklift and Vehicle Safety

Industrial vehicles account for a significant share of workplace injuries and fatalities. Forklifts alone cause tens of thousands of serious injuries each year.

AI Vision can:

- Enforce safe speed and route compliance automatically

- Detect pedestrians in restricted zones instantly

- Monitor blind spots and intersections to prevent collisions

2. Slip, Trip, and Fall Prevention

Falls remain the leading cause of lost workdays and a top driver of workplace injuries.

AI Vision can:

- Identify hazards like spills, clutter, or uneven surfaces before accidents happen

- Trigger instant alerts if a fall occurs, enabling rapid response

- Generate heatmaps of high-risk areas to guide preventive maintenance

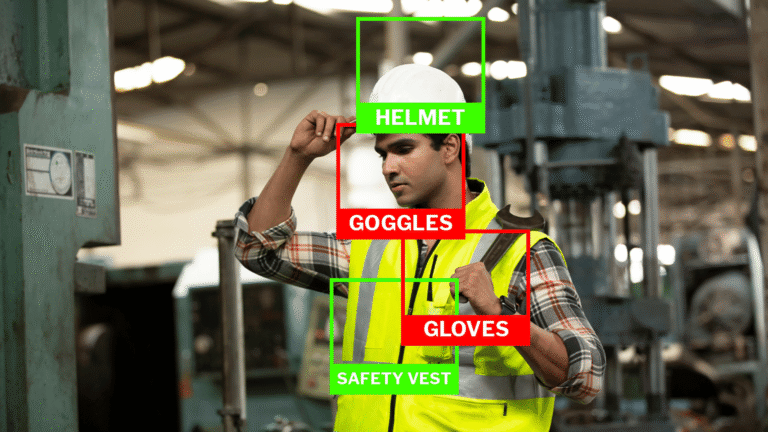

3. Machine Guarding and Compliance

Unguarded or improperly operated machinery leads to catastrophic injuries and costly downtime.

AI Vision can:

- Verify that machine guards are in place before equipment starts running

- Detect unsafe manual overrides or barrier removals in real time

- Create a secure visual audit trail to support compliance during inspections

4. Near-Miss Detection and Analysis

Near misses are often overlooked, yet they’re early warning signs of major incidents.

AI Vision can:

- Flag unsafe proximity between workers and machinery automatically

- Record near-miss incidents for deeper investigation and root-cause analysis

- Identify recurring risk patterns to inform long-term preventive strategies

The ROI of Proactive Safety

Incident prevention is about saving lives, but it also protects profitability and productivity.

- Avoiding just one major forklift accident can save hundreds of thousands of dollars in direct and indirect costs.

- Cutting fall-related claims by even 20% translates into significant annual savings.

- Stronger compliance reduces downtime from investigations, shutdowns, and penalties.

By turning cameras into real-time safety intelligence systems, AI Vision helps organizations reduce risk, safeguard employees, and strengthen operational resilience.

Shaping the Future of Workplace Safety

The future of industrial safety is predictive, data-driven, and AI-powered.

By deploying AI Vision for proactive incident prevention, organizations can move beyond reactive safety checks and create workplaces where risks are identified and addressed before harm occurs.

The result: fewer incidents, uninterrupted productivity, regulatory confidence, and greater trust from employees and stakeholders.